To Part I

Water Tank

When getting started on this project, one of the main things I wanted to fix was the water tank. The tank on the P1k model is too shallow, and there's a lot of space under the locomotive. The Kato model looks better in this regard, and I found that the water tank and air tanks were a separate part too. However, it's cast as part of the chassis on the P1k model and there was no way I was going to try to mill all of that off.

The next option was to see if I could use the Kato chassis. The Kato model itself is nice, but the railings are a bit thicker and, as I've seen others report, the radiator fan housing is too tall (although irrelevant since I would have drilled it out for the KV etched fan grill, and I could have filed it shorter).

Getting it to fit the P1k walkway and shell was a bit more of a challenge than I thought. In addition, the bottom of the chassis is cast at an angle, which not only looks wrong, but would complicate adding a few parts that are needed. I also preferred the rendering of the sideframes on the P1k model (the trucks, including the sideframes, appear to be almost exactly the same as the Athearn RS-3).

So the next option was to try to build up the water tank on the P1k model. This turned out to be easier than I thought.

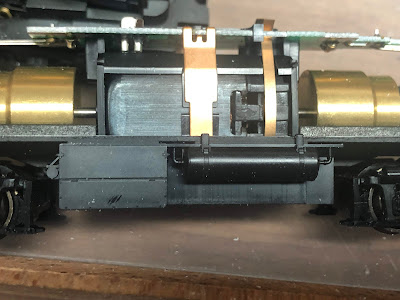

This is the P1k chassis showing the water tank.

This is the Kato model. I also like the air tank better.

This is the p1k model with a built-up styrene tank that fits over the existing one.

I made a rough template using cardstock, then built it out of sheet styrene. The air tank is cast as part of the chassis as well, and it's attached to the water tank, so I had to create a notch on each side to accommodate that. I also didn't make an end next to the battery boxes, because there should be a space between the two.

Toolboxes

At least I think they are toolboxes, one on either side of the water tank. It looks like they are also present on the RS-3s, so I'll do the same thing for those. For the first one, I eyeballed the length in relation to the air tank.

I started with a piece of scale 2" x 12" and glued it to stick out what looked like an appropriate amount. After deciding it should be thicker, I added a second piece. I then glued another piece to create the angled lid.

Next I had to file a small part of the lip at the bottom of the water tank, then used 1" x 8" to glue to the sides. Once that cured, I used sprue nippers to cut the side to shape, and then filed everything to finish.

I built the second toolbox (?) as a separate part. I started by laminating strips of 4" x 12", 2" x 8" and 1" x 8", with all three flush along one of the long edges. I then filed the across the top of the 1" x 8

so it formed the angled lid, essentially by trying to not file the edge the would be against the water tank, and filing the outside edge to the top of the 2" x 8".

so it formed the angled lid, essentially by trying to not file the edge the would be against the water tank, and filing the outside edge to the top of the 2" x 8".

After test fitting, I cut one to length to test.

I made the ends using 1" x 12" then cutting and filing to shape. I also filed the slightly larger rounded radius along the top front, and a slight radius on the bottom front. Because I made a long strip I was able to cut one for both RS-2s, and also will have some for the RS-3s later.

Here it is after I installed some wire piping to both ends of the air tank.

Sanding Pipes

I wanted to try adding sanding pipes, and developed an approach that is easy enough that I may just go ahead and add them to my other locomotives as well.

I ordered a few speed recorder parts to see which ones I liked, and found the Utah Pacific ones had an ingenious method for modeling the conduit. There's a small pin cast coming out of the side, and the instructions have you use a short length of wire insulation as the conduit. Size 32 AWG wire insulation is great for this, just pull the stranded wire out.

For the sanding lines, I used a similar approach. I have spools of 32 AWG wire for installing decoders. This wire has silicone insulation (doesn't melt back when soldering), which is slightly thicker than the insulation from the standard 32 AWG wire that I am using for the speed recorder.

I pulled the stranded wire out, and then inserted .010" phosphorous bronze wire about an inch into the insulation.

The portion with the wire is bent to shape, with a small section sticking out of the insulation, simulating the smaller pipe as on the prototype.

This is then glued with AC at two points on the back of the brake hanger.

All ready to go!

I then thread the flexible portion through the bottom of the chassis, and found a place to glue it inside as well. I then installed the wheelsets for the final bending and trimming of the hoses themselves.

Additional Details

If you look closely at the water tank, I added a sight gauge, as well as an MU stand cover for the Steam Generator Tank fill. There's another one on the opposite side for the Engine water filler.

Parts Used in this post:

The model is a Life-Like Proto 1000 (now Walthers Proto) RS-2

Amazon

This is what I use for installing DCC decoders since the insulation doesn't melt

BNTECHGO 30 Gauge Silicone Wire (Black) 50' spool

Cal Scale (order direct from Bowser)

190-430 Diesel Under Floor Bell (2)

Custom Finishing Models (order direct)

147 ALCO Handbrake Chain Guide226 Fueltank Sight Glass

Detail Associates (find on eBay)

1504 MU Stand - EMD Intermediate, Double

2210 Safety Chain - Black, 40 links/inch