I started this post some time ago and never got around to finishing it. Something to do on a rainy/snowy March morning...

NH DERS-2c (RS-3) 517 on the Air Line at Middletown with a stock car.

Were stock cars common on the New Haven?

Looking through photos, these are the stock cars I've been able to personally verify on the New Haven. I've included the number of stock cars owned by that road, and rankings in parentheses for those roads that were in the top 15 owners of stock cars in 1950.

- CB&Q - 3,573 (3rd)

- DL&W - 97

- ERIE - 82

- MILW - 3,690 (4th)

- NYC - 1,675 (12th)

- PRR - 2,315 (9th)

- SLSX - 713 (Swift)

- WAB - 594

The Swift cars (and Armour, below) would have been destined for their own plants, as photos of the Swift plant in New Haven have shown.

Other cars I would expect may have made it to the New Haven regularly:

- ASEX - 200 (Armour)

- B&O - 1,192 (14th)

- CGW - 150

- CNW/CMO - 3,736 (6th)

- IC - 1,100 (15th)

- Mather - 1,444 (B&O, CNW, and CB&Q leased from Mather, may not be included in their totals)

- RI - 1,207 (13th)

Of course, cars from other roads would be possible. The Santa Fe accounted for 13% of the North American stock car fleet in 1950, and of the 66 roads that owned them, only 18 roads accounted for more than 80% of that total.

But just because these cars were photographed on the NH doesn't mean they were common. How frequently did stock cars actually move on the New Haven? More often than you might think.

I touched on it briefly in an earlier post on commodities because I was surprised to find that swine (in double-deck cars) was the 17th largest group into Connecticut based on number of average annual carloads. This is calculated using the 1% waybill studies from 1950-54, and I was only looking at the statistics for Connecticut (which would also include traffic on the CV delivered to Connecticut).

Fresh Meats NOS (not otherwise specified) was the 6th largest group, averaging about 7,392 carloads annually. But Swine DD (double-deck) was 2,300, plus another 300 single-deck cars, and 250 single-deck cars of cattle/calves. No cars of sheep/goats were recorded. That's an average of almost 8 stock cars/day delivered to Connecticut.

Livestock Traffic

Where does the livestock originate? The cattle to Connecticut tends to come from a bit farther west than the hogs. Major stockyards in those states are listed below. The roads noted correspond to the cars noted above:

- Illinois (Cattle - 100; hogs - 475)

- Chicago - All except DL&W

- East St. Louis - B&O, CB&Q, IC, NYC, PA, RI, SLSX, WAB

- Indiana (Hogs - 775)

- Indianapolis - B&O, NYC, PA

- Iowa (Cattle - 50; hogs - 1,050)

- Dubuque - CGW, IC, MILW

- Sioux City - CNW, IC, MILW

- Minnesota (Cattle - 25)

- Austin - CGW, MILW

- South St. Paul - CGW

- Nebraska (Cattle - 25)

- Omaha - CB&Q, CNW, MILW, WAB

- New York (Cattle - 50; hogs 75)

- Buffalo - B&O, DL&W, ERIE, NYC, PA

- Ohio (Hogs - 225)

- Cincinnati - B&O, ERIE, NYC, PA

Armour and Swift operated out of all of the major stockyards.

As for destinations? Middletown had a slaughterhouse, which is where the stock car in the photo is headed.

Copaco in Bloomfield was another destination, as was Swift and Sperry & Barnes in New Haven. There were other industries and stock pens at Hartford, Providence, Boston, and other locations on the NH.

I have seen it mentioned several times that some of the movements were to the locations with large Jewish populations for kosher meat. That may account for the cattle, but certainly not the hogs. At least in the Bloomfield, Hartford, and New Haven areas there were a significant number of sausage companies.

Models

The majority of these roads can be modeled, including all but two roads that I have documented on the New Haven.

Plastic models have focused on the western roads - ATSF, SP and UP. This makes sense because they owned more than 27% of stock cars in 1950.

The Proto 2000 Mather stock car plays a big part in modeling stock cars east of Chicago/St. Louis. Otherwise, for accurate stock car models, you'll have to look to resin kits.

- ASEX - none

- DL&W - none

- ERIE - none

- IC - none

- Mather - Proto 2000; Sunshine. Owned 1,444 cars, many leased to the following roads:

- B&O - all Mather cars in 1950 (495 single-deck; 438 double-deck)

- CB&Q (1948 - 60 double-deck)

- CNW (1948 - 300 single-deck)

- GSX (Mather reporting marks)(1948 - 4 single-deck; 19 double-deck)

- MSCX. (Mather reporting marks)(1948 - 46 single-deck; 16 double-deck)

- MILW - Sunshine; Westerfield

- NYC - Westerfield

- PRR - Broadway Limited; F&C

- RI - Westerfield (kitbash)

- SLSX - none

- WAB - Yarmouth

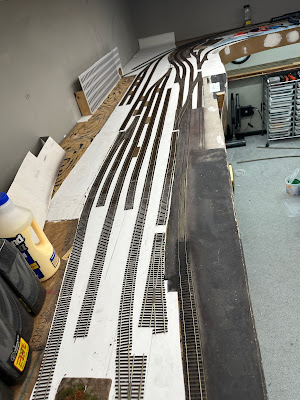

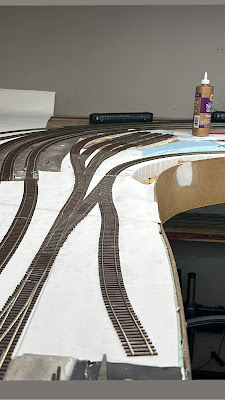

Trains

The blocking information in the Arranged Freight Symbol Books includes some regular livestock movements. For example, SN-3 has a block of New Haven perishable & livestock. But it does not have a block that specified Hartford livestock. Nor does any other train, but cars for Copaco in Bloomfield would have been delivered by the Griffins local, originating out of Hartford.

Also, while many photos on the New Haven have stock cars behind the locomotives, the New Haven livestock block is the second block in the train.

I think it's most likely that stock cars for trains originating in Hartford would have come via Springfield. But it's possible that they could come via Maybrook, and run through New Britain. So the few stock cars I might run would be on a Maybrook freight. Obviously the Mather and Broadway PRR K-7 are the easiest ones to model. But I'll probably build Westerfield MILW and NYC cars eventually, since I think those were among the most common.

There are no industries receiving stock cars (of which I'm aware) west of New Britain on the Highland or Canal Lines. So that's the only train that would potentially have any stock cars on my layout. When the Maybrook-Hartford freights aren't running at all, I won't need any at all.

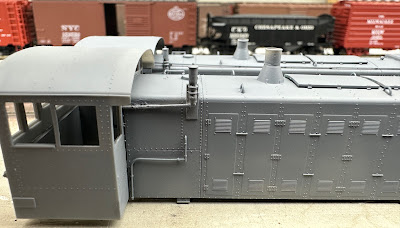

NH DERS-2c (RS-3) with a Milwaukee stock car.

%20with%20MILW%20stock%20car.jpeg)

%200740%20and%200745%20in%20gold%20and%20silver%20gray%20pinstripes.jpg)

.jpg)