Another post to save me the time of repeatedly retyping this on Facebook...

How to clean track is one of the most common model railroad questions or commentary on Facebook, YouTube, and many other online model railroad sites.

In the past, track cleaning was about, well, cleaning the track. That is, getting the (non-conductive) gunk off of the track. However, there are many approaches (some that have been around for decades) that go beyond that and actually enhance the conductivity. These approaches have been reported many times over the years, but it wasn't until a few years ago that Joe Fugate found the answer as to why some worked better than others.

The Short Answer: My Approach

For about the past decade, I've been using graphite. I clean the track with a Briteboy, then apply artists' graphite. Since then, all I've had to do is an occasional spot cleaning with the bright boy and another application of graphite.

The key to the graphite is that it is conductive itself. Later on, I learned more as to why. Note that there are a number of other options for "cleaning" your track which have similar benefits.

The Long Answer: The Science

I'm just reporting and clarifying a few things here, the links I have below have a lot more info and it's Alan and Joe we have to thank for this research and information.

Why Nickel Silver?

One of the things I've found interesting is how many people on Facebook and elsewhere ask whether they should use brass or nickel silver track. I'm not aware of any company that has made brass tracks in a few decades, but there's a lot of it available used (apparently).

The materials are closely related. Brass is an alloy of copper and zinc, while nickel silver is copper, zinc and nickel. That's why some nickel silver can look yellowish or gold, especially when tarnished.

Nickel silver has two advantages. The first is that nickel silver is more resistant to corrosion and oxidation. The second is that nickel silver tarnish is conductive, while brass tarnish is not.

Black Gunk?

If nickel silver oxidation/tarnish is conductive, why do we have to clean it? What about metal wheels vs. plastic wheels (another common question/comment online)?

The answer can be found in a thread on the MRH forum posted by Alan in 2010 reported a chemical analysis that he had sent some dirty track to be analyzed by a lab. The intention seems to have been to determine/verify if the black gunk on the rails was from plastic wheelsets.

As it turns out, it wasn't. It was nickel oxide, and it's inhibiting the conductivity.

"Wait," you say, "I thought nickel silver oxide is conductive."

I was curious, so dug a bit more. It turns out that when nickel silver tarnishes it's called oxidation. However, the yellowish-greenish tarnish (nickel silver jewelry can turn your skin greenish) is actually caused by sulfur in the air. While this tarnish is conductive, I believe it is less conductive than the nickel silver itself (although I haven't been able to verify that).

The black "gunk" that was found on the dirty rail was different. It was nearly 100% nickel oxide (not "nickel silver oxide"). And nickel oxide has an unusual property; it's a Mott insulator. It's a material that should be conductive based on its internal structure but is actually an insulator.

What was more interesting is that in the lab analysis, the gunk appears in random little dots. Although the post doesn't specify it, I found another article that calls these types of deposits wafers. These wafers are caused by micro-arcing between the nickel silver locomotive wheels and the nickel silver track.

The plastic wheels don't have an impact in making the track dirty, although Alan suggests that perhaps metal wheels are better at cleaning the track as they roll over it. With the typical weight of our cars I'm skeptical, but it can't hurt (and certainly looks better).

Cleaning your track requires you to remove these wafers, and they are hard to get off. Simply wiping the track isn't enough. It takes some effort, such as a bright boy or polishing/burnishing the rail. Some chemical treatments might help as well. A piece of masonite is probably sufficient too.

Go Beyond Cleaning

But there's a second aspect that goes beyond cleaning, and that's what Joe Fugate discovered. He did an excellent article that details why: Model Railroad Hobbyist magazine and followed it up later with at least one more Running Extra article.

Joe also did a video on TrainMasters TV that's an update after further research. Preview here.

The key is that rather than simply cleaning your track, you can use something that increases conductivity, which reduces the micro-arcing that causes the black gunk in the first place.

What Joe found is that there are substances that are "Polar" and "Non-Polar." Non-polar substances can help clean electrical contacts, and they also inhibit micro-arcing.

Some very popular track cleaners include CRC-26, Rail-Zip, Automatic Transmission Fluid (which my buddies and I think is the same as Rail-Zip), and Bachmann Track Cleaner among others. These are better than Lacquer Thinner, Isopropyl Alcohol, Acetone and others, as they are semi-polar. But not as good as No-Ox, Wahl Clipper Oil, CRC Contact Cleaner, DeoxIT DS, or...graphite (in a very thin layer).

I think lacquer thinner is popular as a cleaner because it probably removes the black gunk well. But it's not enhancing electrical contact.

Rail-Zip and similar treatments are better than those options, and I suspect they slow the process, which is what makes them better options.

But non-polar options like Wahl Clipper oil or graphite, both of which have been used for decades are much better at preventing the problem. Joe's research explains why.

Any of the non-polar treatments will work well (although Joe has commented that he doesn't recommend using kerosene or gasoline, they are just there for examples). But is one best?

Joe's further research has pointed out that graphene is very conductive. Graphene is a layer of graphite that is only one atom thick. I'm skeptical we can get that when treating our track, but I think it has other benefits. So yes, this would be "best" but I'm not sure it's better enough to say it's the only option.

I haven't done so much reading on chemistry since high school.

Why I Prefer Graphite

Simplicity, and I like the dry application.

First, cleaning the track is (at least) a two-step process. Clean it, then apply a non-polar treatment. In theory you could do it in one step with something like a CMX track cleaning car and mineral spirits. I prefer to consider them separately, simply because I prefer graphite as the non-polar treatment.

All of the other treatments are wet treatments. That makes them potentially harder to apply and could have more of an impact on your ballast and scenery if you're not careful. I also wonder if more dust will stick to the rails if using a wet/tacky treatment.

Another factor is that part of the process of applying the solvent or treatment is to run trains to spread it around the layout (and coat the wheels of the locomotives). Many of the solvents evaporate quickly, while the graphite won't evaporate at all. I think it will spread more completely as a result.

Some of the recommendations I see for other treatments are quite complex. For example, from Choo Choo Charlie in this thread regarding the "proper" application of No-Ox.All contaminants such as plaster, glue, or oil, should be removed prior to No-Ox application. The steps below are all VERY important and none should be skipped.

- 1. Use a mild abrasive such as fine sandpaper or a brite boy on all rails to remove any oxidation.

- 2. Wipe all rails with a rag and alcohol to remove any dirt and fine particles.

- 3. Vacuum all rails to ensure cleanliness.

- 4. Put very thin smears on your finger and rub it on your rails. The total amount of NO-OX-ID “A SPECIAL” that should be applied to 500’ of N scale track is about ¼ teaspoon. If you can SEE No-Ox on rails, you are putting TOO MUCH on! DO NOT APPLY MORE!

- 5. Run all your locomotives, EXCEPT ONES WITH TRACTION TIRES, (no rolling stock yet) over all of your track for at least 2 hours. You may notice some wheel slippage and skipping, (DO NOT PANIC) this ensures that all wheels get treated with No-Ox.

- 6. Remove all locomotives from track and wipe all rails with a clean rag to remove any excess product. Don’t scrub, just rub.

- 7. Wait 24 hours.

- 8. Wipe rails again. Rag will be black.

- 9. For locos with traction tires, turn them upside down, connect track power so that wheels turn. Put a small dab of No-Ox on a Q-tip and apply to all wheels that DON’T have traction tires. While wheels are still turning, use a clean Q-tip to remove any excess No-Ox.

- 10. Run trains and forget about cleaning your track except for occasional light vacuuming.

- THE ABOVE 10 STEPS WERE REVISED 6-10 TO ADDRESS TRACTION TIRE ISSUES AND ARE NOT INCLUDED IN BAR MILLS DIRECTIONS.

- In all cases where problems are encountered it is due to over-application and not wiping off rails. FOLLOW THE DIRECTIONS EXPLICITLY ! "

I don't know about you, but this is a lot of work. I've seen videos with similar instructions.

If you prefer No-Ox, Wahl Clipper Oil, Mineral Spirits, or one of the other non-polar treatments and it works well for you, then I don't see any reason to change. It's always about finding what works for you.

But for me, a simple cleaning with the Briteboy, then a swipe with the graphite on the inner corner of the rail head is by far the simplest. In the past I was running the graphite over the top of the rail, and even that was extremely effective.

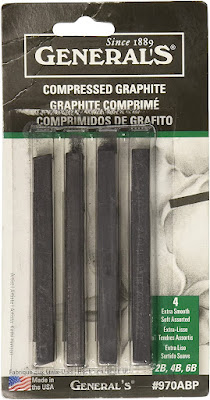

The type of graphite matters. I use regular artists' compressed graphite sticks:

Note that graphite comes in different hardnesses. The scale has HB in the center, with B, 2B, 3B, getting progressively softer, and H, 2H, 3H progressively harder.

In theory, using a harder graphite is good in that it leaves less graphite on the rails. However, hard graphite has a wax binder added, which we don't want. So, stick with the "B" side of the scale. Since your trains will be spreading the graphite around the layout, I think any hardness is fine.

I've also used a No. 2 pencil which is a little cleaner on the fingers. Otherwise, I don't think I have a preference.

Graphite Myths

A common question/comment against graphite is that it's also a lubricant so it shouldn't be used. Of course, so are many of the other treatments.

I have two helixes. I haven't noticed any difference in pulling power in the helixes, but I have enjoyed going years between having to clean the track in them. Even if I could pull one or two fewer cars, that trade-off is worth it.

I've also had somebody say you shouldn't use graphite because it will get all up in the motors of your locomotives. If that's a concern, you're using way, way too much graphite. Furthermore, the brushes in the motor are made of graphite, so I'm not sure how much of any issue it would cause anyway.

Briteboy

It is frequently noted/claimed by folks that a Briteboy is a poor choice, often to the point of, "never, ever use a Briteboy or abrasive cleaner." The idea is that it creates tiny scratches that collect dirt. As we've seen, the issue is deposits caused by micro-arcing, not dirt. Prior to Joe's further commentary on graphene, I figured if there are tiny scratches, they'll simply collect graphite.

However, I do see the possibility that the tiny scratches increase the possibility of micro-arcing. Of course, I have no way of testing this theory. But perhaps it's better to use masonite or a burnishing stick instead of a Briteboy for cleaning.

Track Cleaning Cars

As noted, using the CMX Clean Machine with a non-polar solvent like mineral spirits is probably an excellent alternative. While it's possible that might remove the deposits, I suspect a proper manual cleaning first would still be better.

What about the variety of track cleaning cars with a strip of masonite? While it's probably better than nothing prior to the use of a non-polar treatment, I don't know if it actually applies enough pressure to remove the wafers caused by micro-arcing. Certainly not enough to remove the tarnish. You can always use a stronger method to get a better shine. Furthermore, they don't really target the inner corner of the railhead, which is where you really want to focus your cleaning efforts.

The vacuum cars (Atlas or Dapol) are an interesting option, and those who own them have reported they do well at picking up all sorts of things you didn't realize had been left along the track.

So sure, you can go that route if you want. If I saw one of the vacuum cars priced cheap, I might grab one just to vacuum the layout prior to a session. But I haven't found anything other than the clean/graphite approach to be necessary.

A Final Experiment

As Joe notes, the actual point of contact of the wheels is tiny. The rail head doesn't really fully touch the wheel tread since the wheel is conical in shape. The primary point of contact is the inner corner of the railhead.

A few people online have said that larger rail (Code 100) has better electrical contact than smaller rail like Code 55. This is incorrect, since the point of contact is exactly the same regardless of the width of the railhead or height (code) of the rail.

My buddy Joseph is modeling modern-era and would like to be able to have rusty rail heads, especially on little used industrial sidings, but we don't think dead rail is quite there yet. I did coat the railhead on a bunch of my track with NeoLube No. 2, which is colloidal graphite suspended in alcohol. It worked, and conductivity was good. It has sort of a silvery black hue which looks similar to what I see in a lot of photos on the railhead. The only real issue is that if you need to clean a section of track, it cleans off the NeoLube too. And I'm not convinced it was as good as graphite, although the sections that still have it are still working OK.

Instead, I decided to try a different experiment. I painted some Code 55 with my usual Rustoleum Camouflage (brown). I then cleaned off only the inner corner of the rail and applied graphite. I also cleaned the outer half of a different section of the rail and applied graphite.

Sure enough, the track with the inner corner of the head ran just fine, even though the rest of the rail was covered in paint. The section with only the outer half cleaned didn't.

Randy -

ReplyDeleteGreat post! On Dave Abeles' OC we do the old "rub down" with a wine cork (natural is best) first, followed by the CMC tank car of mineral spirits. All locos get an "isopropyl on towel rub down", and we seem to have almost zero problems. But I'm gonna suggest the graphite to him, and I know that I am going to try it, considering my overburden of short wheel base locos and almost every inch of trackwork having a turnout. I don't use frog juicers, and very few of my engines have current keepers installed, so I need all the help I can get.

Ralph

I've been very happy with it myself, and I know what you mean about turnouts!

DeleteThanks, Randy, Great summation of a lot of info. One other area that occasionally gets a lot of comments is gleaming the rails to eliminate those tiny scratches. Sounds like a lot of work.

ReplyDeleteI've been using graphite for a few years and it does seem to make a big difference.

As an experiment I "painted" the wheel treads on a pair of old metal trucks with plastic whhelsets that were impossible to swap out the wheels without breaking the trucks. I jokingly refer to that as my graphite applicator car though I don't think it's heavy enough to actually transfer and graphite to the rails.

Yeah, I'm still on the fence about burnishing/polishing the rails myself. Mine isn't because I'm lazy, and I've used a bright boy for years when needed, as I haven't been concerned about the tiny scratches. Not really sure how I could test whether it matters or not.

DeleteIn theory just running trains will spread the graphite around as well, so I suspect your application will have some sort of impact.

Randy, Your 2022 rail cleaning recap is, as noted, a fine piece of work. My initial stage is 1500 wet-dry sandpaper...which I feel is burnishing, not sanding. I did originally use 200 grade, and finding that scratching , went to 600 which was much better. But now 1500 is my go to. Also I take extra effort on the inside of the rail head, where the flange hits. Your comments and views on graphite will lead me to try. Great piece.

ReplyDelete