Over time I had added additional staging/storage tracks where I had space. The primary purpose for these is to store locomotives when they are not in use during a session. As I've been preparing the layout for signaling, it occurred to me that it would be useful to minimize the number of turnouts on the signaled track.

There were seven turnouts to staging/storage tracks along the run-through staging track, but by reconfiguring the arrangement, I can reduce that to two. While these weren't in my original staging design, they were dead space and I decided it would be useful to have storage tracks where locomotives not used during the session could remain on the layout.

On this side I'll eliminate one turnout on the main, and the second one is moved to a new location. This will create a "lower staging yard" of four short tracks for the RDCs - three long enough for a pair, and the fourth for a single unit. For 1953 sessions, these trains can operate right out of this location. As usual on my layout, they terminate in the same track as they originate.

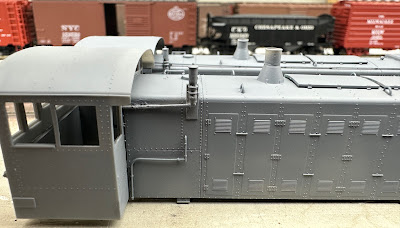

An additional two tracks will go around behind the Agents desk and will be on a grade. That's fine, because it's storage for locomotives. This replaces the turnout that is currently back there to access these tracks. They will be long enough for the A-B-A and A-B-B-A sets of FA-1/FB-2 locomotives.

I have a general idea of how I think I can fit this using Microengineering Yard Ladder turnouts. I did pick up an extra middle turnout (you can see it in the lower right) but came to the conclusion that it wouldn't fit.

If this were for a scenicked portion of the layout, I would have modified the regular No. 5 or No. 6 Microengineering turnouts so I could curve them to follow the main, but in this case a straight ladder is fine...provided I can get reasonable radius curves to enter and exit.

I have a further two yard ladder turnouts to fit at the far end, so I mock up some ideas there too. I've tried drawing things out like this, and spent some time in the past with some of the CAD programs designed for model railroads but have found that nothing is as good as just working with track, for me. In part because as I see where things lie, I see other options and can tweak the concept instantly.

I had some cork sheets left over from making the cork board at the Agent's desk and they were the correct thickness so I used those as the roadbed and started connecting track. I'm shooting for a minimum of 26" radius here, but 24" will work just fine if I have to do that.

This process involves ensuring that the tracks not only fit for this section, but that I'll have enough clearance at the far end for the curve to the second part. At this point, it looks pretty good.

Of course, prior to gluing it down I want to test it with the RDCs too in order to make sure they are long enough.

Looking around the corner, I've switched to Woodland Scenics foam roadbed sheets, since that's what Roger had in stock, and also their 2% grade starters to get up to the higher benchwork as it goes around the corner.

I have a window cut out in the utility room to access behind the Agent's desk. I need to fill in the track where I removed the turnout - easily accessible but hidden while operating from the layout room. Locomotives can be stored here from the clearance point of the turnout, and I took care (using 85' passenger cars) to ensure clearance around the corner of the desk and between the tracks. The main line track will run along the edge of the cork roadbed, and I can move it further out if needed, to ensure the storage tracks won't interfere with operations.

On the other side, I've already moved the main line turnouts. Like the other side, I had HO scale cork roadbed in the original track arrangement. I found it easier to rip that all out and use the foam sheets instead.

To make this side work, I have a couple of Walthers curved turnouts, one curved Peco, and the rest standard Microengineering ones that I had on hand. I've tried a number of configurations and landed on this. It eliminates 4 main line turnouts.

One track will be sized specifically for the Comet and another track for spare cabooses. That will leave two longer tracks for storage of diesel locomotives not in use. The track through the ladder goes to the Walthers turntable used to turn locomotives during the session. I went with the Walthers one because the controller has a button that will turn the bridge 180 degrees, which is really all I need it for. But I will have room to make storage tracks for the steam locomotives when the time comes.

I used insulated joiners to isolate these storage tracks, and may also add switches so I can turn them off during sessions.