New Britain Station Main Site

Wednesday, March 30, 2022

NH 600-series Coaches

Wednesday, March 23, 2022

Progress: More Trackwork

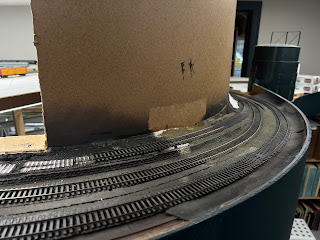

Coming around the helix you and you'll be at the start of what is continuous industries. I've made a few modifications here. The two tracks in the front of the photo with the hopper and the tank car are Hardware City Fuel. I moved these over to make room for one additional track, for the City of New Britain, with a chlorine tank car.

The more obvious change is the addition of two tracks connected to Track No. 5 on the far side of the main tracks. These are DK Coal and Miner, Read, and Tullock. I had been postponing these because of the diamond crossing in the middle of them. I used another of the new Walthers turnouts (24' and 20" radius curved) for Miner, Read and Tullock.

The 30-degree crossing is from the excellent new Diamond Line from Fast Tracks.

While it probably needed a different angle, and at least one of the tracks curved through the crossing, I didn't want to handlay this one. Not just because of the challenge, but this product is the first that actually looks like a prototypical crossing, with cast parts.

I deviated from the design, though. It comes with pieces of rail that you install and then solder to PC board ties at the far end to keep everything in gauge. Instead, I trimmed away the last few wood ties and removed several ties from Microengineering flex track, then slid the rail into place in the castings. The ME track keeps itself in gauge, and it also let me curve the tracks right up to the frogs.

I'll fill the gaps with styrene. I need to get a Dual Frog Juicer or some other autoreverser to power the two inner frogs.

If these were available when I built the tracks for Shurberg and New Britain Lumber, I definitely would have used one. But that is set quite a distance away from the fascia and is already in place. I'll look at potentially changing it, but I don't think I will at this stage.

In this section, the only track that needs to be completed now is the Stanley Svea track that extends past the Household Fuel silos and onto a curved trestle. It won't stop me from being able to operate, but I'd like to finish that relatively soon too.

Wednesday, March 16, 2022

Poultry Cars on the New Haven?

Rick Abramson (see his layout tour here and part 2 here) asked a question on the NHRHTA Forum about whether live poultry cars operated on the New Haven. My initial response was going to be, "If we know that the New Haven shipped this (at least once), certainly poultry cars ran on the line."

But then I started to dig to confirm what I knew (and didn't) and as usual, the post grew...

The 1% waybill analysis of 1949 listed only 1 car (7 tons) from Indiana to New York. In 1948 it captured 1 from Indiana to Delaware, 2 from Indiana to New York, and 1 from Iowa to Pennsylvania.

The problem is, with so few of these cars, the 1% data may be incomplete and inaccurate. This would imply that there were only 100 carloads in 1949, all destined to New York, and 400 in 1948. Could this be correct?

Unfortunately, I haven't been able to find complete waybill analyses prior to 1948. Time to find some other sources.

The primary resource regarding live poultry by rail is an article by John H. White, Jr, (the senior historian for transportation at the Smithsonian Institution) published in Agricultural History 63.3 called Home to Roost: The Story of Live Poultry Transit by Rail.

Kristin Dummler also posted an excellent clinic on the history and modeling of poultry cars. Kaylee Zheng has also presented clinics on these cars.

These resources cover the history of the cars and their use, so I'll focus on the question: did poultry cars run on the New Haven?

Baby Chicks

I'm not sure baby chicks are included in the Live Poultry classification. Because they didn't need to be fed for 72 hours, they were shipped in boxes the same day they hatched, via Railway Express Agency. And many of them from the New Haven.

Here's an Along the Line article from June 1942 where it notes that Hall Brothers Baby Chicks in Wallingford shipped 16,000,000 chicks that year:

But that doesn't address the question of live poultry cars.

Live Poultry Traffic by Rail

Live chickens, turkeys, pigeons, and probably other poultry used to be shipped by rail. As noted by John H. White, Jr., the late '20s saw an average of 12,000 carloads nationwide annually, with 2,800 live poultry cars in service headed for most major cities in the country. In 1928 51% of live poultry was shipped by rail. By 1940ish it was down to 27%, lost primarily to competition by trucking. The WWII spike was 3,376 carloads in 1944.

In terms of the poultry cars themselves, by 1947 there were only 237 cars, and only 15 in 1950. The low quantities listed in 1948-9 are reasonable, although probably a bit below the actual totals due to the low number of cars and shipments.

John's article notes that a survey history of the industry published in 1973 indicates Live Poultry car service ended in 1956, but the railroads continued to report live poultry shipments until 1961. I can't find any Live Poultry cars listed in the 1953 or 1954 ORERs. Regardless, with only 15 cars remaining, the live poultry by rail business was all but over by 1950.

Of the live poultry traffic, he reports up to 60%+ was destined to New York City. Fleshing this out are some statistics I pulled from 1921 Legislative Documents for the NY, NJ Port and Harbor Authority mentions that the majority comes via the Lackawanna due to a special poultry facility at Hoboken that transfers the poultry to trucks bound for the West Washington Market, and over 175 local chicken slaughterhouses throughout the city.

A 1936 edition of Decisions of the ICC in 1933 notes 73.5% of all live poultry movements via rail were to New York City, this was 67.4% in 1934. Of those, 66% of shipments originated in Illinois or further west. Live poultry sourced from farms closer than Illinois came primarily via truck.

An AAR Report on Poultry and Dairy Products from 1947 indicates that 79% of the national live poultry traffic was destined for New York City in 1940, but this was down to only 38% in 1944, with terminations in Illinois rising from 4% to 21% during the same period. In this report it also notes that the number of terminations is too low to get reliable statistics for individual destinations. This is because the source of the carload data would be the annual 1% Carload Waybill Analysis, but it highlights how this data was used in numerous reports and studies produced by the AAR, government agencies, and industry groups.

John also mentions that "much of the live poultry shipped to New York, Boston, Philadelphia and Washington originates in the Del-Mar-Va peninsula." This statement (because of that "Del-Mar-Va peninsula" wording) appears to be taken from the 1947 AAR Report. Of course, traffic destined for Boston from Delaware, Maryland, or Virginia would very likely have been routed over the New Haven.

He notes that New York City was the largest market because as much as 80% of the live poultry in NY was destined for orthodox Jewish households, which is confirmed in several of these other sources. The 1918 issue of Traffic World reports that Italians in New York City also preferred live poultry to dressed. It also mentions that poultry cars would often be loaded as L.C.L and make multiple stops along the way to pick up more birds. Interestingly, the national fleet at the time was 891 private cars and 114 owned by railroads. It doesn't specify which roads owned live poultry cars, though.

The New Haven railroad also served large Jewish communities in (West) Hartford, Norwalk, Bridgeport, and New Haven in Connecticut, Worcester and Boston in Massachusetts, and Providence in Rhode Island, among others. They would require the same live poultry deliveries as New York City, although local New England farms could have addressed much of that demand, but perhaps not all. As roads and trucking improved in New Haven territory, these could be served from local as well as centralized sources.

The reports have specifically mentioned Boston, and even some of the tables have included data for that city, although not data that I could use to derive carloads for live poultry. It would be nice to find some confirmation for other cities on the New Haven.

New Haven Documentation

Is there anything we can find in New Haven published documents? Poultry cars would have been a very small percentage of New Haven traffic, but they are mentioned in various freight documents.

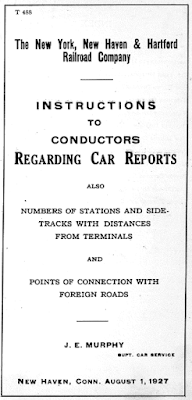

For example, the 1927 Instructions Regarding Car Reports (replaced in 1944 by a simpler document that just lists station numbers) identifies abbreviations for each type of car to be used on car reports. Live Poultry is listed here (LP) as is Palace Horse (RK). Both rare moves but still noted in the rules.

This 1948 booklet covering a lot of rules for freight also has information regarding live poultry cars.

In most freight rules they would fall under the "live stock" category and aren't called out individually, neither are beef and swine. But rules such as these examples show that at the very least, live poultry cars were expected to be on New Haven rails periodically.

Live poultry is mentioned in a November 1928 article about the new Harlem River express facility in Along the Line. No details, just that it is received. I'm sure there are probably other mentions through the years. As an express facility they could be referring to baby chicks.

Other Documentation Mentioning the New Haven Railroad

In a 1911 Report of the Railroad Board the New Haven Railroad reports transportation of live poultry in the amount of 530 car miles for cars owned by Live Poultry Transportation Co and 136 car miles for cars owned by Lemac Car Co. These are definitely live poultry cars, and not baby chicks via REA.

This is confirmation that such cars did run on New Haven rails. Unfortunately, that's all it provides, the car miles traveled. No destinations.

--

A December 1946 report/proposal to build a new wholesale market for fruits, vegetables, poultry and eggs and New Haven has some specific information:

"These firms receive the bulk of their poultry and eggs from midwestern sources by rail and truck. Most of the carlot rail receipts in New Haven are received at the firms' rail spur tracks. The volume by rail has shown a steady tendency to decrease during the last 10 years. This decrease has been counteracted by heavier truck receipts. Since 1940 a few of the national packers have built broiler processing plants in New England and the Del-Mar-Va area. Those plants deliver both boxed and ice-packed poultry to their local branches to meet their requirements for fresh-killed poultry."

"...New Haven is the leading poultry and egg market in Connecticut...approximately 120 cars of eggs, 110 cars of poultry, and 60 cars of turkeys of shipped-in supplies were handled by all wholesalers in the New Haven area in 1945."

"Rail receipts were from western production areas and were received principally by local branch houses of national and independent packers. Most of these firms have rail spur tracks from which they can unload their rail arrivals directly into their stores."

Reading through the report, it's not always clearly differentiating between rail and truck traffic when referencing "carlots." So we can't determine the volume of traffic by rail. But it does specifically state that live poultry is received by both rail and truck in New Haven, and it mentions they are delivered on their own spurs. So again, live poultry cars and not baby chicks via REA.

That covers a period from 1911 to 1946 with specific information regarding rail transportation of live poultry on the New Haven which, other than baby chicks, moved via live poultry cars. The answer is yes, live poultry cars did run on the New Haven Railroad. This is also right at the tail end of live poultry car service.

Dairy and Poultry Statistics 1955 shows all live poultry into Boston came via truck from Maine, Massachusetts, and New Hampshire. Rail service is still indicated for Chicago.

Modeling

From a New Haven Railroad modeling standpoint, most won't need any of these cars. But we can certainly say that occasional live poultry cars to New Haven and Boston are a regular, although maybe not even weekly, occurrence.

Frequency would be higher through at least 1930 and might have picked up again for WWII. But I doubt there were any new destinations, just more traffic. We have confirmation that they continued through the late '40s to New Haven at least, and probably Boston. So those modeling New Haven or the Shoreline, or the electric territory, prior to 1947 can reasonably justify a car or two.

Would they be seen on anything other than Shoreline trains? Perhaps depression-era and earlier cars to Hartford and maybe smaller cities like Waterbury or even Danbury, especially pre-1928. After 1928 trucking would take a larger percentage so I think that by 1940 New Haven and Boston may have been the sole destinations remaining for rail service. Even with the 1946 report, traffic dropped precipitously enough that there were only 15 cars still in service, so I think it's safe to say that they weren't running on New Haven rails by 1950, and maybe gone as early as 1947.

Wednesday, March 9, 2022

Progress: Trackwork

Finishing up the trackwork. I've frequently said, "don't be afraid to make changes."

Well...

Track No. 5 - First Modification

A few years ago, I extended Track No. 5 coming into the main portion of the layout. The initial idea was to extend the track as far as I could and provide a point where the eastbound freights could shove a cut of cars. To do this required creating a level track because it's at a point where the helix is already descending. It also gave me an opportunity to put in a nice retaining wall for the track separation.

When I later made modifications to the backdrop so I could include more industries on the north side of the tracks, it also meant I could more easily include the East Main St. crossing.

Track No. 5 - Second Modification

The problem was now that there was only room for 2-3 cars before the East Main St. crossing. Either the freights would have to shove the freights all the way past E. Main, meaning the rest of the track was pointless, or I needed to find a different solution.

I decided to install a new entrance to Track No. 5 so that it would start just to the west of East Main. That left a portion of this track for an industry.

Track No.5 - Third Modification

Track No. 5 - Fourth Modification

Walthers Turnouts

The two turnouts in this location were the old Shinohara/Walthers ones. I needed curved turnouts with a 26" or 28" outer radius. I could have handlaid them, but these were much faster. The two primary issues I have with them is that they are Code 100, and the points aren't sprung. Obviously, the details themselves are nowhere close to Microengineering, but I felt that based on the location I could live with that.

But Walthers just released their new version. They are Code 83 and have sprung points. Like the old ones they are 28" outer radius and 24" inner. Although that 24" is less than my mainline minimum of 26" they have been well tested in this location and have worked fine with my equipment.

I also picked up one with a 24"/20" radius for the industry track coming off of Track No. 5 (which, not being the main track, has a radius of 24").

Thursday, March 3, 2022

2022 Goals

Yes I know it's three months into the year already, but I have some deadlines this year.

The first (but later) deadline is that I will be hosting some operating sessions and an open house for the 2022 Northeast Region NMRA Convention from September 15-18.

The second (but sooner) deadline is the New England RPM which was recently announced for June 10-11 this year. I plan to be on the open house and, with luck, an ops session on the Thursday before.

Hindsight 20/20 for March 5

Before these, though, I have another deadline to meet. I'm doing a quick clinic on the RS-2s on Saturday for the latest Hindsight 20/20 virtual meet. Don't forget to register!

All track installed

- Two main layout turnouts to install

- PF Corbin

- Two industry tracks with crossing to install

- Russwin Power

- Stanley Svea track

- Bulk Tracks

While I've noted a number of them as "not essential" since we can operate without them, it would be worth getting them done. The Bulk Tracks is probably the most complicated, since it has a swing bridge to get to them.

Feeders

- Liftup

- East main line and industries

- PF Corbin

- Stanley Works

- Bulk Tracks

- Some staging

- Turntable

While the turntable won't necessarily even be needed when running the 1953 sessions I expect to run, it is easy to connect. I do want to make some additional locomotive storage tracks there, however, probably with manual switches to turn the tracks off when not using them.

Locomotives

- 44 Tonners (0805, 0813)

- RDCs

I can work on plenty of others, but these are all I'll need for the ops session. So I need to finish the 44-tonners.

Paperwork

I have the waybills that I have used for prior ops sessions, which is fine, but I plan on making some new ones to provide a little more work, particularly for Stanley Works.

Throttles

I need to get the ProtoThrottles set up, I'm still waiting for the receiver. I have two ready to go and would like to get one more for the Stanley Works crew. For now I'll most likely run the passenger trains with the regular throttle. I think that will be easier since the runs are short and we'll have to select different power for each run.

--

Not Required for Ops Sessions

That's all that is technically required, but I would like to have more completed on the layout by September in terms of scenery.

Ballast, Track, and Groundcover

I enjoy this process and, at least around the track, I approach it as a single process. It should go pretty quickly once I get the track and feeders done. I'm still finalizing my process in the meantime and will probably have to take a day to go sift some more ballast.

I'm not sure I'll get to switch machines and other small details, although I ought to do joint bars prior to painting/weathering the track.

Roads

There aren't too many left to add. I'll need to finish the ones with grade crossings so I might as well do the rest at the same time.

Line Poles

These are simple, well underway, and add a lot to the visual aspect of the layout. This can include other small infrastructure details like electrical boxes, etc.

Signals

I'm not sure if I'll finish them by either session, but I'd like to try. At the very least I could get non-operational signals in place, and work on the electronics later. But since I need to make sure the wiring is prepared for it, there's a reasonable chance that I might get them completed by then.

One major aspect to the signals is that the mainline switches need some sort of switch machine to detect their position. This will be much easier to do before I (re) ballast, so should be a priority. The challenging ones will be the ones on the first level of the helix.

--

But right now I need to go practice squeezing a 90-minute clinic into 30...