I've been working on the fascia for the staging level.

New Britain Station Main Site

Friday, February 26, 2021

Layout progress - Fascia and workspaces

Wednesday, February 24, 2021

More Freight Ops from an old Trains Magazine article

I recently got a copy of an article called Passengers and trailer trucks ride the New Haven from the February, 1950 issue of Trains.

It's a 7 page article including pictures and includes quite a bit of interesting information. More than half of the article is regarding passenger traffic, and how the New Haven was (is, at the time) the only Class I railroad to show a profit from their passenger operations, depending on the calculation used. Even using the I.C.C. calculation which includes all expenses, including rents and taxes, they operate at a modest loss, but much less than any other road.

But about a page of the article talked about how the New Haven moves trailers on flat cars, which was still a new approach at the time. The New Haven wasn't the first, but it was close to it, starting their service in 1937. But what really caught my interest started with,

"I rode the caboose of a trailer train from Boston to New York one night..."

While the recollection of the trip itself is interesting, (37 trailers, on 25 flats on BH-1 which totaled 36 cars that night, hauled by DER-1-c/DL-109s 0740 and 0752, he was late for the trip because he had trouble locating the train in the yard, but the train was running at least 15 minutes late anyway, etc.), it's the operational information that can be pulled from the article that is of most interest to me.

Because they were late, they were switched to run on Track 2, the eastbound main (running westbound) so they "could run around the Extra which was somewhere down the line on Track 1. This gave me the chance to watch block signals working in reverse: as we passed them, the cleared from red to green, with a brief flash of yellow in between."

So I'll have to dig a little bit to see what sort of logic I'll need to put in place for the signals for running against the traffic.

"Conductor F.J. Fielding was busy at his desk in the front of the car, checking waybills and making a work sheet which showed at a glance just what would eventually happen to each of the cars on the train: drop a load at Readville, pick up 35 loads and 5 empties at Providence; take on 3 loads at New London and drop one off at Cedar Hill. That was the end of his run."

While the desk facing forward makes sense, I don't think they were turned on a regular basis. But the conductor writing out their own switch list from the waybills is quite interesting. The more I'm finding, the more I think that the conductor on a road job or local freight would write up their own impromptu switch list, which may or may not have used an official form. While within a switching district or yard limits, I think it was more likely handled by the agent, yardmaster, yard foreman, etc.

In any event, for model operations, I still like the idea of some sort of desk (rolling or permanent) for the crew to use to organize their work. Regardless of who is preparing the list, it's also pretty clear that it is done before they get to town. For example, in this article we read that they learned of additional work in Plainville before leaving New Britain. Which means the conductor could plan their work on the way, instead of not knowing what additional work they might have when they arrived. In this article, rather than receiving orders that were hooped up, they stopped and called ahead. I can also say that in my own experience on the CNZR, the crew has stopped and called the office for clarification or instructions on what to do. They also plan their moves ahead of time.

The main point here, is that if you are running a freight that will have work on the way, unless you are working a switching crew within yard limits, you'll have a plan on exactly what moves you'll need to make to finish your work in a town before you get there.

The article then talks about some of the complications of running late. They switched back to Track 1 at Readville, but were then slowed by Train No. 537, an except-Sunday local from Boston to Providence. They were able to pass the passenger train at Attleboro when it cut off its engine to pick up a couple of cars of express. It also started raining, which put them farther behind schedule.

I'm not sure why the rain itself slowed them down, but this is one of the most interesting tidbits:

I've always been of the impression that such cars would simply make the next train. It doesn't indicate that they were hot cars, but it does become clear later in the article that this train doesn't meet the midnight deadline to get cars off of the road to avoid another day of per diem charges. So that may have something to do with it."It had to wait up at Providence for three cars from UP-1, the New Bedford-Providence freight."

"The night fleet of passenger trains had crept up the rear and passed us. No. 181 had a 15-minute layover in New London, so BH-1 was stabbed while that mail and express train occupied the westbound main.

""The other side of the job" as Conductor Fielding called HB-2" was apparently also running late, passing at New London.

"We came to Cedar Hill Yard. Both the conductor and the flagman went to the front platform of the caboose. At precisely the right moment they uncoupled the car from the rest of the train. The train proceeded to the westbound classification yard, while Conductor Fielding dropped off of his rolling office and took his sheaf of waybills to the yardmaster's office. Flagman Patchelder braked his buggy to stop on the caboose track and hung out the yellow lantern which indicated he would sleep on the car that night."

They left Cedar Hill at 4:30 AM with 71 loads, no empties, with 3 motors (electric locomotives, type and road numbers are not noted). Just south of Bridgeport they had a hotbox 23 cars back and, "An hour went by while the train crawled slowly to the next siding and dropped the offending car. It was a bad spot for a set-off: an upgrade and with the last half of the train hidden around a curve. Engineer Horan, running blind as he backed to pick up the tail end, had to keep his speed down to a crawl."

They arrived at Harlem River three hours behind schedule.

I find a lot of interesting operational opportunities here. There have been a number of ways that modelers have tried to incorporate problems like a hotbox into their operations. I'm not sure how frequently something like that should happen. I think that they would be of most interest on a layout with long main line running. Having to slow to a crawl for however long it takes to get to the next siding would have the biggest impact on that type of layout. Even with a 4:1 fast clock, an hour is 15 minutes of real time, and that can have a real impact on the operation of a railroad.

What is much more common on a model railroad, though, are curves. Paying attention to what the engineer could see from the cab should affect how they operate the locomotive.

I also found the passage about kicking the caboose down the caboose track very interesting. And in a model railroad yard, having a caboose or two with a yellow lantern out also brings in prototypical operations.

I don't have the whole issue, but interestingly I noticed in the table of contents there is also an article on welded rail.

Monday, February 22, 2021

Oops

Friday, February 19, 2021

1932 ARA Standard Box Cars

Yes, I got sidetracked again...

When cleaning up I put my freight cars into a rolling cart for storage. To make finding cars easier, I grouped them by prototype, and one drawer is 1932 ARA Standard box cars. Naturally I have more of these than I actually need, since it's readily available as a plastic RTR model produced by Atlas. Information is also easy to come by in the form a very thorough and fascinating book by my friend Ted Culotta of Speedwitch Media, The American Railway Association Standard Box Car of 1932.

While these models have been out for quite a while, I haven't seen the info compiled on one place.

In my notes from prior to the initial release, I thought they intended to release ten different body styles. To date they have released seven. In the book, I had noted which prototype matched the different body types, but as I go through that again I find that my notes don't match the actual releases so far. I had compiled the info from a number of (now forgotten) sources when the models were first announced. I am skeptical that three more variations are in the works at this point.

The models themselves are well done and they clearly designed the project to cover as many of the prototypes as they could accurately. Here are the seven body types.

Type 1: "Long tab" body, Murphy Panel Roof, 4/4 Dreadnaught Ends

I included the PRR car, because a lot of modelers might think the Pennsy had a huge roster, so they have to have one. However, they only had a single car, No. 36986, the only car in class X35. This was because they received one of the 5 prototypes (No. 3). NYC also had but a single car, No. 100000, which was ex- ARA No. 1. The other three prototypes, Nos. 2, 4 and 5 because C&O 1900-1902. In addition, UP only built a single car to the design.

The major components (ends and roof) are correct for these cars. I'll get into the smaller details in a moment.

This was the most common style of this prototype, covering the following roads as built:

- ARA 1-5 (5)

- C&O 1900-1902 (3)

- CofG 4000-4499 (500)

- CRR 5000-5249 (250)

- MEC 4248-4999 (752)

- MP 30750-31399, 31500-31999 (1,150)

- I-GN 17001-17300 (300)

- MVCMVX 9000 (1)

- NOT&M 17301-17400 (100)

- NYC 100000 (1)

- PRR 36986 (1)

- UP 182500 (1)

- MP 31400-31499 (100)

- MP 32000-32499 (500), and NOT&M 17401-17500 (100)

- WM 27001-27500 (500), 27501-28200 (700)

The first group of these also used a Duryea cushioned underframe. The second group had W-corner 4/4 Dreadnaught ends and Duryea underframes. While the Speedwitch underframe would be appropriate for the first group, I don't know what the differences were for the 1939 or 1942 built cars. National Scale Car Co. has a Z26 version as part of their Rock Island and CMO mini kits that is good at least for 1944-45, but I don't see it listed as a separately available part right now.

--

A note about underframes: I separate out the cars with Duryea underframes because they have features that can be seen at the end of the car, and also under the car in profile (even in shadow). There were some other more minor differences in the underframes that could be modeled for several other cars.

The first 550 of the C&O cars, and all of the Erie and NKP cars had the older ARA center sill, due to lack of availability of the new center sill components when built. This isn't noticeable unless you turn the car over. In addition, the L&A, NC&StL, Seaboard, and WRT cars had a truck center spacing of 6-1/4" wider than the other cars. This means the outer edge of the bolster is in line with the rivet seam between the outer side panels, instead of just inside it (about 7/100ths of an inch in HO).

Type 2: "Long tab" body, 11-panel flat riveted roof, Flat riveted ends

- L&A 15000-15150 (150)

- SAL 17000-18999 (2,000)

- WRT 900-919 (20)

There's an excellent article on upgrading the Seaboard model in the Seaboard-Coast Line Modeler V3.1 (Q1, 2009).

Type 3: "Short tab" body, Hutchins radial roof, 4/4 Dreadnaught ends

- C&O 7000-7649 (650)

- NKP 13000-13499 (500)

Type 4: "Short tab" body, Viking roof, Buckeye ends

- ERIE 76500-76999 (500)

Type 5: "Long tab" body, 11-panel flat riveted roof, 4/4 Dreadnaught ends

- SOO 41800-42978 (even numbers), 135800-135998 (even) (600)

Type 6: "Long tab" body, Viking roof, 4/4 Dreadnaught ends

- NS 25000-25499 (500)

Type 7: "Long tab" body, Murphy (rectangular) panel roof, flat riveted ends

- NC&StL 18000-18499 (500)

Other 1932 ARA Standard Box Cars

I was pleasantly surprised at the number of variations offered, considering a number of them were for a single road. Yes, the molds are designed to be interchangeable, but it still increases the cost of the project. To date, though, there are a still a number of cars not covered by these variations which will be more difficult to model. I've already noted the M-I and WM cars that had W-corner Dreadnaught ends.

- BAR 65000-65499 (500), 65500-65549 (50), 65550-65649 (100)

The most interesting one, perhaps, (and my old notes indicated they may have been body types 8 and 9) is the Bangor & Aroostook. The initial order of 500 was built for newsprint service, and had thicker floors than the standard car. This affected the interior height, but not the external characteristics of the car. But they opted for 4/5 Dreadnaught ends instead of the 4/4 style used on all of the other 1932 ARA Standard cars that used these ends. The second two groups of cars were the last 1932 ARA Standard box cars built, in February and December 1945. The first 50 were similar to their other cars, but the final 100 used the (then) new 3/4 Improved Dreadnaught Ends. So modeling either of these with the existing Atlas model will require replacing the ends.

Fortunately, F&C have a resin kit for the first 550 cars.

- CGW 89000-89998 (500), NdeM 60000-612999 (1,300)

Another unique variation. Like the SOO cars, these used a 12-panel flat riveted roof. But the biggest difference was the 7/8 Murphy ends (was this the last application of these ends?). They also had a unique door only used by these two groups. Initially, I thought this would be Type 10. But Atlas has released Type 5 models lettered for the NdeM, so I'm taking that as a sign they are not planning on it. This, unfortunately, is a true foobie. But since NdeM cars are rare, I guess they figured it was a valid scheme for the prototype as a whole.

- CP 225000-225699 (700)

Like the 1937 AAR Standard Box Car, Canadian Pacific had their own unique variation of these cars as well. It's interesting that they built these, in part because the side sill design for their "Minibox" cars is seen as probably a direct influence on the 1932 ARA Standard car. In any event, their version used 4/5 Dreadnaught ends, and a Murphy Radial roof. The Murphy roof has only one stiffening corrugation in the center of each panel instead of the two that the Hutchins Radial roof used. So trying to start with a Type 3 body requires more than just replacing the ends.

F&C also makes a resin kit for the CP cars.

- D&H 17626-17725 (100)

Built in 1937, it used 4/5 Dreadnaught ends like the B&A and CP cars. But what makes these unique is the early use of welded construction. The first group of 10 was almost entirely welded, including the side sheets, underframe and ends. The last 90 had a few more points where rivets were utilized, but still had welded sides and ends. So not the easiest variation to kitbash. With its welded sides, this would be a good choice for Pierre at Yarmouth Model Works, since he has mastered creating the oil canning effect.

Doors

Overall I'm very pleased with the quality of the casting of the Atlas cars. For example, while nobody makes bracket grabs as well as Kadee, these are on par with other injection molded models. They also took the effort to tool two door variations to account for the most common door hardware used. This includes the Camel Roller Lift and Creco Ball-Bearing styles. Along with the doors available as a minikit from National Scale Car Co with Union Duplex hardware, you can have the correct options for any of the styles Atlas produced.

Brake Wheels

They tooled at least 5 different brake wheels. I don't have a CRR model, which should have a Klasing brake wheel. However, I don't remember anybody indicating Atlas had done a Klasing brake wheel prior to the one we produced at True Line Trains. Since those aren't available now either, you'll have to go with the Resin Car Works/Shapeways one, or wait for rumored one from Kadee.

Other Details and Comments

- The only significant detail that's really missing is the air hose.

- The retainer valve is "missing" but the pipe with brackets is nice and it will be easy enough to add a proper retainer to the top.

- The bottom-operated uncoupling lever was standard on all except the CP cars, although they tooled it as a straight handle rather than the 3-bend handle that is rendered well on Detail Associates and other bent wire detail parts.

- The end grabs are both applied as drop grab irons. This is correct for the CofG, CRR, I-GN, L&A, MP, MVCMCX, NOT&M, NS, SAL, WM, and WRT. The C&O, ERIE, NC&StL, NKP, and SOO all had straight grab irons attached to small brackets below the end sill, and the MEC cars had a bracket-mounted one to the left of the coupler, and a straight grab iron attached to the end sill to the right. I suspect that other than the MEC variation, few modelers will make any changes.

- Poling pockets and the attached uncoupling lever bracket are not accurate for all cars. This is understandable, and expected on a mass-produced car.

- The brake gear is molded as part of the underframe, with a separate cylinder and reservoir and the AB valve is very rudimentary. The exact placement looks to have been fairly consistent so it's generally OK, but you certainly don't get the proper profile under the model with regards to the rodding, etc. So replacing the cast rodding with stand-alone would improve the appearance. There was some variation based on photos, though. The prototypes had an early version of the reservoir that is quite evident. Ted's book is the best resource if you are looking to accurately replicate these features.

- I have not looked at any variations in trucks yet. I'll do that when I get around to detailing and weathering a given car.

Painting and Lettering

Wednesday, February 17, 2021

Along the Line - December, 1940 - Jointless Rail

This is an interesting article from the December, 1940 Along the Line.

8 ½ Miles Jointless Rail Now In Track

''What makes The Bankers so late this morning?"

The query was addressed to the information clerk at Hartford

station by a man who had just come from the subway passage under the tracks.

"It wasn't late," was the reply. "It left here

five minutes ago."

"Good gosh!" the man exclaimed, "I've been

standing there in the subway for over ten minutes and I never even heard it!"

And thereby hangs a tale.

He was one of our regular commuters, and had formed the

habit of waiting in the subway, reading his paper, until he heard the vibration

when his train headed in on the station viaduct. But this particular morning

there was no noticeable vibration. Nor has there been since. And welded rail is

the answer.

The Hartford station viaduct is equipped with jointless

welded rails, each 840 feet in length. This was the New Haven Railroad's first

experiment with this new development in track construction and it has proved

eminently successful. It has been followed by additional installations

elsewhere and in all likelihood the future will see much additional track butt

welded to form continuous rails of a thousand or more feet in length.

We now have altogether a total of 45,106 feet, or about 8-1/2 miles of welded rail in place, on bridges, through stations and grade

crossings, and tunnels. Bridges were chosen for first installation because of

the elimination of vibration through elimination of the impact at joints, with consequent

lessened wear and tear on the bridge structure. Grade crossings and stations

were next chosen because the expense of maintaining joints is greater in those

places; at crossings it involves tearing out and replacing- part of the roadway

material: and at railroad stations it often involves tearing out and replacing

portions of polatforms.

The longest stretch of welded track which has yet been laid

on the New Haven is 3,600 feet through the Terryville tunnel. This was welded

at Bridgeport yards into 1,200-foot sections and these field-welded in the

tunnel to make continuous rails from one end of the tunnel to the other without

a break.

The longest single stretch which has been welded and moved

in one section to date was 1,421 feet for each of the two rails for Track 2

through the Fair Haven tunnel, while two 1,407-foot rails were placed in Track

1 at the same location. These were welded at the Bridgeport yard and moved on

flat cars to the tunnel.

A close-up inspection of a railroad rail would make a layman

very doubtful of the feasibility of transporting rails of such lengths on

flat-cars except on a perfectly straight stretch of track. It appears to be so

rigid that it would seem impossible to bend it but actually there is sufficient

flexibility so that the rail will bend with the curvature of the track.

The ordinary rail length is 39 feet, so that in ordinary

track there are two rail joints for every 39 feet of track. These joints

represent the point of greatest wear in rail because each wheel which passes

from the end of one rail across the small gap to the beginning of the next,

strikes that next rail the equivalent of a heavy hammer blow. When tracks are

welded together it makes one continuous smooth surface and thus eliminates entirely

track joint maintenance and at the same time makes for very much smoother

riding track.

There are two methods of doing the welding job - by an

electric annealer or by the oxy-acetylene method, the latter being the latest

development and the method used bv the New Haven. The abutting rail ends are

heated to a temperature of about 2,280 degrees Farenheit, using a

mechanically-oscillated welding head that applies heat evenly to the rail sections

from all directions. Simultaneously with the application of heat, the rail ends

are forced together under a pressure which attains a maximum 2,500 pounds per

square inch

Next, in order to achieve a refinement of the grain of the

metal in the vicinity of the joint and to relieve internal stresses set up

during the welding procedure, the ioint is uniformly re-heated to the critical temperature

(about 1,380 degrees Farenheit) and allowed to cool in the atmosphere. In a

test of the strength of such welded rail, a load of 50,000 pounds was rolled back

and forth across the joint of a welded rail, supported as a cantilever, two million

times without any failure developing.

Other locations where welded rail of varying lengths is now in

service are Sackett's Point Road, Toelles crossing, Ward Street, Wallingford

station, Parker Street, Hosford Street, Lee's Crossing, Mooney's, Cooper Street,

Cherry Street, South Colony Street, Meriden station, Cross Street, Brittania

Street, North Colony Street, and Warehouse Point bridge, all on the Hartford Division.

1. A typical rail joint showing wear from constant impact of

wheels.

2. A finished weld.

3. Oxy-acetylene welding apparatus at work welding two

rails.

4. A close-up of the flames showing how they are brought to

bear on the rails from all directions at once.

5. The complete weld, before finishing and polishing.

6. Removing upset metal with Oxy-acetelyne cutting machine.

7. Grinding and polishing.

8. Finished rail loaded on flat cars.

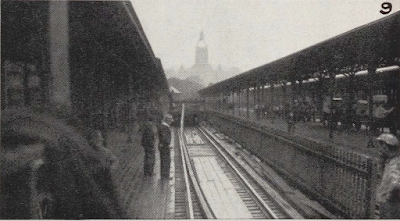

9 and 10. Unloading the rail where it is to be placed in

track, by means of pulling the flat cars out from underneath.

11. The other end is anchored so that engine can pull cars

out.

12. The finished job of continuous train at the Hartford station.

I was surprised to see that the New Haven was installing welded rail prior to WWII. I wonder how much more was finished by the end of the '40s, even with the war.

Monday, February 15, 2021

Gondola Plate Loads

As my buddy Dick pointed out in the comments, it looks like these two are from the construction of the lift bridge at Cape Cod in 1933, with the wheel being a cable sheaf. He points to lots of photos at the Library of Congress. Thanks, Dick!