As you may know, Chris' layout grew out of a Shoreliner article by our friend John Wallace and his experience as a teenager when he was able to ride (and fire) the Valley Local. The article details the work of the day quite extensively, and John has continued to provide insight and information to Chris as he builds his layout.

Chris gave me a copy of this article a while ago, and I thought it would be worth posting here. This is from the October 1946 issue of Along the Line, a (usually monthly) employee magazine.

The article doesn't list an author, and it appears to be a railroad employee writing it. It covers a day on the Canal Local - not the YN/NY freight through New Britain, but the local freight that handles the traffic on the south end of the Canal Line. At the time of this article it was NHDX #4 (later NX-18).

After leaving New Haven it serviced:

- Highwood

- Plasticrete

- Mt Carmel

- Cheshire

- Milldale

- Plantsville

- Southington

- Plainville and back

Picks up and sets off over-dimension cars at Highwood. Connects at Plainville to & from HDX #5.

This train is very similar to the Valley Local. The Canal Line by this era is freight only, and in Manual Block territory, but there's only a single local freight. The freight houses in Mt. Carmel, Cheshire, Milldale, Plantsville, and Southington are all served by truck, not rail. It originates in New Haven, and turns at a junction and small yard at Plainville, and exchanges cars with another local freight. It would be very easy to model with New Haven as staging, and the east/west Highland Line, along with the north branch of the Canal Line also going to staging (or stub-ended). The cars from HDX-5 could simply be waiting in Plainville Yard.

Day Train Order stations are at Mt. Carmel and Milldale (Bob Belletzkie has helped get the train order signal operational at Milldale again).

I don't have assignments before the April 20, 1948 Engine Utilization report, but on that day it was DERS-2b (RS-2) 0503 and it reports that it was a 55 mile run that day. Since it was assigned an RS-2, it may have been assigned a J-1 or R-1 when it was still running steam.

In April, 1949 it is assigned DERS-1b (RS-1) 0670. That locomotive lives on (sort of) on the roster of CNZR. It's not operable right now, but Dale and I continue to hope...

By fall of that year it's DEY-5 (S-2) 0620. No. 0606 is assigned in October, 1950.

By April 1952 it had been upgraded to DERS-2c (RS-3) 533, then 550 in fall of that year, 594 in fall 1954, 560 a year later.

In September of 1956 it's now a DEY-7 (SW-1200) 651, and in April, 1957 it's 652.

A Day on a Way Freight

There are few railroaders

who have more of a finger on the pulse of business than the crew of a way

freight. And few get closer to our customers. The way freight crew know which

plants are busy and which are in the doldrums. They know what new plants are being

built, and where expansion is planned. They know these things because they live

with the industries in their territory. They know and talk with our customers.

They are friends.

The five men who run the Canal Local are just such a crew.

This train leaves New Haven each morning around 9:45 a.m. to serve the

industries on the "Canal", or Northampton Branch, as far as Plainville.

Not only do the men know all their customers, but even know most of our

neighbors who live adjacent to the tracks. And they perform little extra

services for many of them, .in addition to giving

them bang-up railroad service.

For the shipping clerk at Clark Bros. plant at Milldale,

they have a Boston newspaper. A dozen or more of their customers look for delivery

of copies of ALONG THE LINE each month, as do also some of their friends in

houses along the right of way. At Southington they invariably drop off a

piece of ice for Rose Verderame, clerk at the freight office. And returning the

compliment, in wintertime Rose always has a cup of hot "Java" for the

boys when the way freight arrives.

There's no doubt about it—this way freight job is a friendly

job! The crew of the Canal Local enjoy their run and you would have a hard time

weaning them away from it. The three train crew members alone have a total of

one hundred and fourteen years' service between them right there on the "Canal"

line. Leading off is Conductor Abram D. W. Holmes, Jr." Ducky" to you

and to all his customers and railroad buddies from New Haven to Plainville.

"Ducky", who lives in Springfield and deadheads back and forth to New

Haven every day, has operated on the "Canal" line for forty-two

years. He knows every tie and rail joint on the line, and the family history of

the occupants of most of the houses within sight as the Canal Local shuttles

back and forth delivering and collecting freight at the plants and stations en

route. And he recalls that his wife's grandmother rode down from Northampton to

New Haven on the old canal in pre-railroading days. It took her a night and a

day to make the trip.

Frederick Henry Miller is the "flag"-his buddies know him as "Highball" ("Because I'm so fast," Fred modestly admits)-and he's been working the "Canal Local" for thirty-six years, as has his partner, William A. Cumm, brakeman, known to all and sundry as "Biddy". "Biddy" lives in Haydenville, Mass., and gets home only at weekends, going home Saturday evenings and coming back to New Haven Monday mornings. During the week he makes his home at the Railroad "Y". "Highball" lives in New Haven. He is one of three Miller brothers, all of whom were working on the "Canal" at one time, and they were affectionately nicknamed "Highball," "Fishball" and "Cannonball". Another brother, Benny, still works on the New York division.

Brakeman "Biddy" Cumm and Conductor "Ducky" Holmes

Flagman "Highball" Miller

The day we rode the caboose of the Canal Local as guest of "Ducky"

Holmes, it was pouring rain most of the time-but the boys take that right in

their stride. Togged out in oilskin hats, rubber raincoats, and boots, a bit of

rain doesn't bother them at all.

On the head-end was Engineer Matthew O'Dea and Fireman James Cavanaugh. Pulling out of Water Street Yard at New

Haven, our train, with five freight cars, rolled through the east cut and across

the main line tracks and then "across lots" through the "Canal"

cut, right through the city of New Haven, past the Arena, past the old Grove

Street Cemetery where rest the remains of Noah Webster, Lyman Beecher, Eli Whitney,

Samuel F. B.-Morse

and other distinguished New Englanders; and then, parallel to Winchester and

Dixwell Avenues, out to Hamden.

Matthew O'Dea was at the throttle

Passing through Hamden, "Ducky"

called attention to an "A" pole at the entrance to Winchester's powder

house reservation. It's a pole similar to a whistle post, except that it has

the letter "A" instead of a "W". As our train service readers

will know, but others probably not, this means that before entering the gate

with a cut of cars the air must be coupled up.

Passing Winchester's, in Hamden

Coming· to a plant on the

west side of the tracks, Conductor Holmes explained that this was the Plasticrete

plant, where building blocks are manufactured out of cinders. "There's an

industry I've seen grow in just a couple of years, from a single tiny building

to that big plant-and they're constantly expanding. We handle a lot of freight

for them. Just shows the power of a new ideal"

Monument to an idea: The Plasticrete plant

At Highwood siding we picked up

one load and two empties—high cars which would not clear the bridges through

the cut in New Haven and so had to be taken around via Plainville. Then we passed

from the New Haven Division into Hartford Division jurisdiction.

At the W. I. Clark siding, a car

was set off loaded with cork for a new freezing plant they were installing.

At Mt. Carmel, on this

particular day, there was nothing but company mail. But on the siding, placed

there the day previous, was a huge bridge girder, loaded on three flat-cars and

destined to be used in the building of the bridge over Whitney Avenue which is

a part of the extension of the Wilbur Cross Highway.

The Canal Local carries mostly heavy

freight-steel, lumber, feed. "Down by this next bend," remarked our

host, "is Munson's house--he's the superintendent of the cemetery - and

they always ring a bell and wave to us as the train goes by, or if it's after

dark, signal with a flashlight." Just friendly stuff!"

And over here on the other side -the

woman in that house always waves to us. Oh, that's her daughter, Mary, out

there today. She had infantile paralysis."

At Cheshire we picked up one car

at the Cheshire Ball & Socket plant, and while "Highball" was

flagging his job, the manager of the Cheshire Coal & Lumber Co. came over

to pass the time of day.

Cheshire Ball & Socket plant

Beyond Cheshire, the. old canal

became very much in evidence, running alongside the tracks for miles at a

stretch. The water apparently is stagnant.

In places the old canal is much in evidence

At Milldale one car was picked

up, and the Plainville cars were swung behind the Atwater Manufacturing "drops" since

it is difficult to go in there with too many cars. The Atwater plant

manufactures clutches and other items for Ford cars. At the Atwater plant two

cars were dropped and three picked up.

At Atwater's the caboose was cut off while cars were switched.

There were no drops or pick-ups

that particular day at the Blakeslee Drop Forge at Plantsville, but Conductor

Holmes stopped there to telephone and get the "dope" on how much

Atwater freight would be ready for pick-up on the return trip.

Blakeslee's, Plantsville

At Southington Harry Blanchette

and Rose Verderame greeted the Canal Local. Rose got her ice and Harry, who is

the son of Agent Harry Blanchette at Willimantic compared notes with the crew.

'

Plainville was reached about

2:15. There all hands took fifteen minutes to fortify the inner man at a local

lunchroom and then proceeded to do the local work at the several plants there—Peck,

Stow & Wilcox's hardware factory, Southington Hardware, Tubular Products Co.

(during the war they turned out miles of tubes for airplanes), Southington

Lumber (a Diamond

Match affiliate), and Pratt & Whitney's. The last-named plant covers an

area a quarter-mile square and the Canal Local handled for its construction

over 200 carloads of piles, 68 carloads of wooden blocks, and a great deal of

other material, as well as hundreds of cars of highly important materials when

the plant started operations.

Peck, Stow & Wilcox

At Plainville the train was

turned on the "Y" and cars left by the Hartford Local were picked up

and then, southbound, there was repetition of the northbound trip—stops to drop

or pick up cars all along the line.

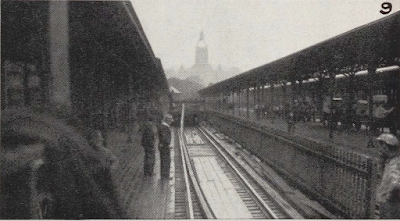

Turning on the "Y" at Plainville

Back at Water Street at 6:40

p.m., "Ducky" was fortunate enough to be able that day to make No. 80

home, after checking in at the Yard Office. Another day's work accomplished, customers

satisfied, and then-home!

Just a day on a way freight.

--

The first thing that comes to mind when I read this (again) is that for the most part, railroading is the same thing every day. The crew knows their territory very well, and they know where there are challenges (don't bring too many cars at Atwater, for example).

I want to work this into my sessions where I can by having a seasoned "qualified" operator as conductor to teach new operators (as engineers) the line. I will also detail how the crews work New Britain. In my case, since they are switching crews, it will vary a bit more than a local freight.

Chris has detailed his solo sessions on two of his freights on his blog, and they are also a great tutorial for crews who will work the jobs:

The stop to call and find out how much work there will be on the way back is also quite interesting. Even where the freight houses are served by truck, there will still be an Agent and a phone. We saw in the Along the Line article following BO-5 that the crew received orders at New Britain for work in Plainville. Now we can see that even in this era before radios that the crew could also check with Agents down the line for additional work.

Industries continue loading/unloading cars through the day. So the crew won't know what all of their work is when they leave in the morning. Adding work through the session is not only prototypical, but makes the operations more interesting. I'm also always looking for confirmation on how to do it more prototypically than just stopping and checking the bill box at every industry.

This is a small freight, with only 5 cars to start, a great model railroad local:

- Picked up 3 at Highwood siding.

- Set out one at W. I. Clark

- Pick up one at Ball & Socket

- Picked up a car at Milldale and blocked the train for Atwater.

- Dropped two and picked up three at Atwater.

They arrived at Plainville with 10 cars. Two of those were cars from their original consist leaving New Haven. These must have been for the industries in Plainville, although the article doesn't specify the work that was done. This local worked Plainville, so any cars on HDX-5 for Plainville would have been left for them to deliver. The 3 over-dimension cars would be for HDX-5, and they would also leave any outbound cars that had originally come via HDX-5. We don't know how many cars they returned with, nor how much work there was on the way back.

Note that they didn't leave any cars along the line to pick up on the way back, as we frequently do (and John recalls the crew doing) on the Valley Line. They picked up 5 on the way.

As small as this job seems, it's still a full ops session job, and would take (me anyway) 3-4 hours to complete, which is a full day with a 3:1 or 4:1 fast clock.