This gives me a post to refer to when responding, instead of writing it over and over again.

Obviously, I'm a DCC guy, and find that there are a great many benefits. But this isn't intended to convince somebody using DC to convert. Just to provide some info to address some common myths, even after all these years. If you want to stick with DC, that's just fine with me!

Myth No. 1 - It's Complicated

You don't need to know about CVs, programming, etc. to use DCC. You need two things:

- The DCC system needs to be connected to the track. You do this the exact same way as DC. Two wires, or a bus, and make sure there are no shorts. A short in DC is a short in DCC. And if your locomotives work on the layout in DC, they will work with DCC.

- You need a decoder in your locomotive. This is where I think there's a lot of mystery about it's purpose and how it works. So here's my explanation.

With DC, you control the power and direction of the locomotive directly through the track. The polarity determines the direction, and the amount of voltage determines the speed. Very simple.

With DCC, the track voltage is always at the equivalent of full power on a DC throttle, and you don't have to be concerned about the polarity. Instead, your throttle tells the decoder how much voltage, and the polarity, to apply to the motor.

In order to do that, each locomotive has an address. By default this is 3. If you're only ever going to run one locomotive at a time, then there's no need to change this. Press Loco on your controller, then 3, then enter, and you're running a train.

Otherwise you'll want to change the road number. This will be a little different on each system, but it's often the only programming you'll ever have to do. Some stores (online or brick and mortar) will set this for you if you ask. Otherwise I'll use the MRC system as an example. No need to connect a programming track, you'll do this on the main. Just make sure there is only one locomotive on the track with the default number of "3."

- Press Prog

- Select Prog Main Track

- Press Enter

- Type "3" to select locomotive No. 3

- Press Enter

- Adr will flash on the screen

- Type the number that you want to use for that locomotive (usually the road number).

- Press Enter

Although another option will flash in the screen, if all you are doing is changing the locomotive number, then just press Loco, type in the new road number to select it, then press Enter. You are now ready to run that locomotive under that number.

For the majority of modelers, it doesn't need to get any more complicated than that. However, there are many other features that DCC offers that you can't do easily, or at all, with DC. This includes things like consisting, sound, speed matching, tweaking motor performance, etc. I'm not going to say that these are all simple, and some systems are better than others in these regards.

Myth No. 2 - Wiring is Complicated

I'm sure we're all familiar with the, "DCC only needs two wires," marketing copy. While it's technically correct, in practice you'll probably want to do a bit more. The bottom line is, if the wiring is sufficient for reliable running under DC, then it is for DCC too. But I have a few comments:

DC can often be far more complex to wire than DCC. This arises when you want to be able to run multiple trains independently at the same time. So you have to create different electrical blocks, with separate controllers, etc.

With DCC you'll need multiple throttles as well, but you don't need to wire in blocks for independent running. This is one of the biggest advantages in my opinion. It's often described as, "controlling the train, not the layout." In other words, you don't have to worry about flipping switches on the layout, or not running into a block controlled by another throttle as you might with DC. You just choose your locomotive and run it.

You might use separate blocks to install circuit breakers in case somebody causes a short (a derailment, for example) in one section of the layout. By doing this, that short won't shut down other sections of the layout. But it's not required.

It's also much easier to wire a reversing loop in DCC. With DC you usually have a manual switch (although there are options to automate it). But there are more options with DCC.

Some other areas you'll often see mentioned are using boosters. A booster is needed only when you are drawing too much voltage. That's determined by the number of locomotives and how much each locomotive draws. The number of boosters doesn't have anything to do with the size of the layout itself. a 4' x 8' or 40' x 80' layout can both be run on a single booster. If you're considering DCC, start with one and see what your actual usage requires.

Then there's the idea of "DCC Friendly" switches. This isn't a defined term, so it means different things to different people. Switches should generally not be wired for power routing. Some use it to refer to whether the frog is powered or not. Another common description is when the points are electrically connected. All of these situations will work for DCC.

If your layout is already built, then yes, there may be some alterations that you might choose to make. The advantage to a powered frog is the same as DC, it prevents stalling (particularly for small wheelbase locomotives). I'd recommend that the points should be electrically isolated whether DC or DCC, but they will work with either.

But if you have a fully wired DC system, with blocks, etc., then converting is certainly something that may require some work. In fact, for a reasonably large existing layout I would consider this a more valid reason to not convert than probably any other.

Myth No. 3 - It's Expensive

Obviously, "expensive" is a relative term, so what you consider is expensive, somebody else may not. So instead let's say, "it costs money."

Unless you have a fixed budget for all the money that you will ever spend on your layout in your lifetime, the question isn't about how much it costs, but whether you'd prefer to spend the money on something else. You could buy several more freight cars, or get a DCC system. Get a new locomotive, or install a decoder in one or more existing ones.

Certainly if you have a large roster of locomotives, then converting them all to DCC may be a considerable expense. If you actually use all of those locomotives on a regular basis, then this may be a very reasonable reason not to switch. Having said that, I've known plenty of people with extensive rosters that have used a number of approaches to switch.

In my observation and experience in this (and other) hobbies, people will spend money on something if they want it enough. If DCC doesn't reach the level of "want it enough" then you probably won't spend the money on it.

That's really the reason why people don't switch - they don't think the potential benefits are worth spending their time and/or money on. "It's too expensive," is really, "it's not worth that to me."

The fact is, the DCC system will usually cost less than the benchwork. Or the track. There's a good chance that it's less expensive than the switches and wiring needed for a complex DC block system. Or many other things. If you consider what you'll spend on your layout over a lifetime, a DCC system isn't going to rise to the level of a "major" expense. So you'd rather spend the money on something else. Nothing wrong with that.

Myth No. 4 - "DCC Ready" Means Something

"DCC Ready" is a marketing term. It is not defined, and thus can mean something different to every manufacturer. There are two general categories, though.

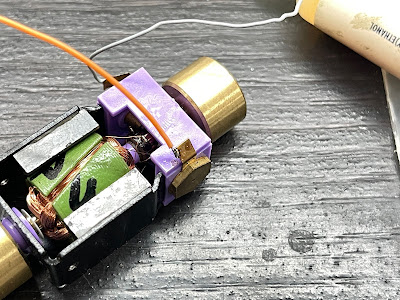

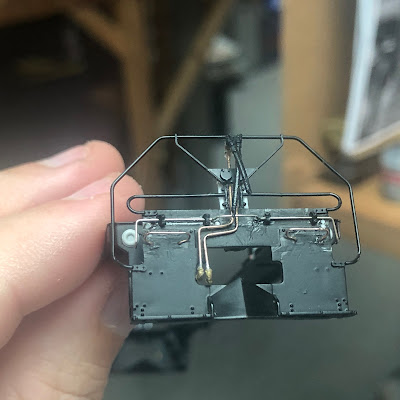

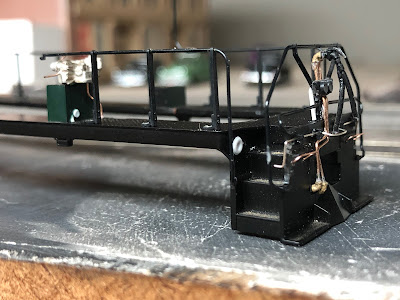

Newer models, that were released in DC and DCC versions in their initial run, generally just need a decoder added. Those that were initially released with sound may even already have a speaker installed. Regardless, they were designed with a place for the decoder (and for sound units, a speaker). This makes it very simple to upgrade.

Older models, that weren't initially designed for DCC, can be more complicated. I've purchased "drop-in" decoders for a "DCC Ready" model that required some modification of the frame to fit. I've had others that required you to cut several traces on the circuit board when you install a decoder.

I usually remove any circuit boards when converting an older model.

The fact is, any locomotive can be converted to DCC. But older ones can be somewhat complicated. My advice is to plan on paying somebody to install a decoder if it's an older model, regardless of whether it's "DCC Ready." If you learn how to do it, or it's a simple installation, then all the better. And sometimes "paying somebody" is working on something else for a buddy who installs a decoder for you.

DC(C) Works for Me

This is not a myth.

If DC works for you, then great! It's worked for decades and will continue to do so. I do understand that if you are happy and continue to use DC that you'll be subjected to a lot of people trying to convince you to switch. Again, that's not my intention here, but on the flip side I do think most people will find operating with DCC "better" and want to help dispel the myths that might prevent you from switching.

I would recommend that if you prefer it, then don't bother justifying why. If you say, "it's too expensive," then somebody will try to prove to you that it's not expensive, and may actually cost less than the DC system you're building.

Just tell people you're quite happy with how it's working for you, and it's what you're using now. In particular, I wouldn't say the reason you are sticking with DC is one of the ones that I've listed, because many folks will see that as an invitation to dispute that myth.

It really doesn't matter why somebody chooses to use DC or DCC.

Why DCC?

Like I said, this post isn't intended to promote DCC over DC, but I think it might be useful to know why I use it. This is probably more for new modelers rather than those who have used DC for a while and are happy with how it works for them. But for those on the fence, or new to the hobby, why consider it at all if it will cost more for a DCC locomotive than DC?

I mentioned several advantages like independent control of locomotives, consisting, motor control, etc. Overall, I think DCC is more flexible, and offers many features that DC just doesn't. The ease of installation (of the system, not decoders in locomotives), are all reasons for me. As a prototype modeler, I want my model railroad to operate like the prototype as well. This includes how the locomotives move, things like sound (because the use of the bell/horn and a number of other features) is important for actual operations. But that's me.

But the No. 1 reason why I prefer DCC is its ease of operation.

Most of the reasons that people give for not switching to DCC are focused on the layout owner. This makes some sense, since it's their layout and they are paying for it. But as somebody who has operated on dozens of layouts, I can tell you that it is absolutely the best option for operating somebody else's layout.

I can go to a layout that operates using DCC and immediately know how to run my train. I've also operated on a number of DC layouts, and it's always a much more complicated process. For the layout owner, who is used to their particular block and control design, it may seem simple, but for a visiting operator that's usually not the case.

With DCC all I need to know is the road number (or consist number), select a loco, and run my train. It's the same on every DCC system.

This is also one of the main reasons I love the ProtoThrottle. It's very intuitive, and simple. I'm also not interested in more "advanced" DCC capabilities. For example, I've operated on layouts where turnouts were controlled by DCC. This is fine if everything is operated by a Dispatcher, but not if each operator is expected to control switches from their throttle.

Like DC, the layout owner will say, "it's easy." But I find that in both cases we spend more time asking for help in getting the layout to work when I'd prefer that my focus (as an engineer) is on my train. I appreciate it from a technology standpoint. But I don't want to use it.

I want it to be simple for operators coming to my layout.

What System?

If you do decide to go with DCC, obviously, I'd recommend MRC, which I've been using for over a decade, although I'll be switching to ProtoThrottles for the actual throttle. So any base system that works with them is fine with me.

But when asked which system I recommend, the answer always starts with whatever your modeling buddies use. They will be your first point of technical support, and can also bring throttles over so you don't have to buy several at once. Around here that would be NCE. I'm comfortable going my own way, so will stick with MRC. I'm not a fan of the Digitrax design, but they are also a very capable system. Outside of the "big three" there are varying degrees of features, flexibility, and complexity and you'd have to be willing to go that route knowing that you many not know anybody else that uses that system. Although I think a lot fewer modelers use MRC, I can say that I know it is a fully capable system, like NCE and Digitrax. On the other hand, I've never used something like the Bachmann system, so I can't tell you if it has all of the core features I'd expect.

Each system does have its strengths, and since I'm not familiar with all of the latest features of all of the many systems, I'm not really qualified to answer anything more than that generalization.