New Britain Station Main Site

Friday, May 28, 2021

Improving Intermountain AAR 70-ton Flat Cars

Friday, April 2, 2021

More Rivets!

Modeling buddy Bill Gill contacted me after he saw my post on rivets with yet another technique he has developed. I have to reiterate this is one of the main reasons I like blogging, getting new information, techniques, and ideas from others. It's also great to hear from Bill, who I first met at RPI, and with the current state of the layout still in limbo (plus the pandemic) I miss seeing him a few times a year.

This is an Athearn flat car he modified to match a D&H flat car for the NEB&W at RPI.

There are 2 replacement rivets over the grab iron, 8 rivets between the first two stake pockets, then vertical rivets (3, 4, 8, and 3) noted by the arrows. I have to say his are more precisely placed than mine are on the flat cars I just did...

Here's a look at the finished and weathered car with a marble load.

The rivets on these cars are tiny dots of thick cyanoacrylate applied to tiny needle pricks that located the precise spot for each rivet. I printed the patterns on a piece of Scotch Magic tape and applied that to the side of the car to use as a guide for the needle marks. It took a little practice to get the feel for how much pressure to apply to the needle (held in pinvise) to get consistent size/depth, but that came quickly.

Then a bit of practice applying just the right amount of CA. A tiny dot of CA was picked up with the needle point and carefully lowered until just the bottom of the droplet touched the tiny divot.

If I got too much CA on a spot, a quick, flat scrape with tip of #11 blade removed it and I made another needle poke before trying again. It sounds more tedious than it is once you get the feel for it.

One improvement I made on later projects was to use JB Weld epoxy instead of CA. It has a much longer working time and was easier to wipe off when I goofed. It also settled better to a more uniform looking rivet head than the CA, which sometimes set pretty quickly.

I'd had a terrible time trying to harvest and use Athearn rivets, The smallest Tichy rivets were a lot bigger than the rivets on the Athearn flat cars I was trying to match and (at that time anyway) none of the Archer rivet spacings matched the Athearn spacing.

I got overly optimistic and tried this method for applying a double row of staggered rivets along the center of a tender's sides. Too many rivets to be absolutely consistent in size and spacing.

But I managed to gently scrape those off and sand away the needle marks with just a little work with 600+ grit wet dry paper. I then found some archer decals that worked ok although I wish they were just a tiny bit larger and kept the same spacing.

Thanks for the tip, and fantastic model work as always, Bill!

Friday, March 19, 2021

A Pleasant Surprise

Tuesday, September 15, 2020

What else? Smoke Stacks

One day Chris mentioned that if I were to build the tall smoke stack to scale, it would go to the ceiling. I hadn't gotten around to checking and just had a Walthers smoke stack as a stand in.

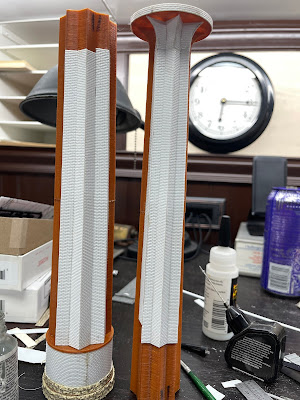

So, what are we looking at? There are three smoke stacks that will be on the layout. Two at Russell & Erwin, and one at Stanley Works.

These are the two at Russell & Erwin. The Sanborn maps give the heights, but not the width which I estimated using the scale on the map. Despite the appearance at this angle, the star-shaped one is taller. These are 10' x 150' on the left, and 15' x 175' on the right.

What about the Stanley Works one? In one of my clinics I pointed out the really long ladder, which is what I think might have inspired Chris to point out I'd have to build the things.

I took this photo in 2015. It was demolished on March 18, 2018, so I now know it was built in the '20s, it was made of steel (I thought it might be iron), and was 12' wide and 196' tall. It's also separated from the power house by a bit, which is good since it's all that will fit on the layout.

So, how do those compare with the Walthers model? The Walthers one is 1.25" x 10.5" or a scale 9' x 76' or a bit short.

To scale, the Russell & Erwin ones should be 1.3" x 21" and 2" x 24" tall.

The Stanley one is 1.65" x 27" and as it turns out, the outer diameter of 1 1/4" PVC pipe is 1.65" so here's a mockup:

I left the Comet and caboose projects in place to help with the scale. To give an idea of how undersized the Walthers model would be for these specific industries, here it is next to the scale sized one:

The question is, of course, do I build them to scale? I think I'll try. If I decide to scale it down, how much would I reduce it? I'm not sure. The two Russell & Erwin ones, of course, are very obvious in the Cochrane photo I cropped above and tower well above the train.

I'll need to put a bit of a taper on this one for Stanley Works, and then either carve or make a wrapper for the steel plates, along with Archer rivets. And a lot of (Tichy?) ladders. For the shorter of the Russell & Erwin ones, the same approach with either a styrene or paper brick wrapper should work. As always, the challenge will be the star-shaped brick Russell & Erwin one. I've pretty much decided the best way is to 3D print it. It's just a question of seeing if any of my 3D printing buddies can do a 2-foot tall smoke stack in one piece.

Glad I'm not modeling O-scale!

Tuesday, September 8, 2020

What else am I working on? Embassy Diner

A small but signature structure on the layout will be Embassy Diner. It's located next to the tracks on Main St. and is right at the front of the scene. It's a typical 'railroad car style' design, but there isn't a commercial model that will work here.

Despite its location, I don't have all that many pictures of the diner:

This is from 1930:

I think this one is from a little later (it's from a very low resolution photo):

They aren't great, but they are from a different angle than I have for others, and the second one shows the relationship to the crossing gate very well.

The next photo I have is from 1960. I don't know when the lettering on the side changed but I'll probably use this style.

It's the best photo I have. Like the station, there's a shoeshine set up, but this conveniently has a cover so it will be pretty easy to model.

I don't have a date for this later photo, but the coloring has changed:

Although the crossing gates aren't visible, I'm pretty sure this is the last paint scheme it had based on this photo after it is abandoned:

Again, I don't have a date, but it's past my era regardless. I don't know who the photographers were for any of the pictures.

Using the rough dimensions (40' x 10-12') from the Sanborn map, I decided to put together a sketch drawn to scale. I estimated other dimensions based on an 80" tall door on the side.

I thought the windows looked too square (and still do), so the ones on the right are 1mm narrower than the ones on the left. I then decided to play around with the trick of drawing an 'x' on the original drawing and this one. Although the perspective is different, the points where the lines cross will be in line on either.

Despite my imprecision, the cross points pretty much line up where they should, which means my sketch should be pretty close to correct. Looking at the larger version of this picture, the bottom of the windows should be about shoulder height based on the figure walking in the door on the end. The 1930 photo shows the windows to be more square than they might look, but they still look like they should be a little narrower to my eye.

I estimated the windows to be the same width as the door, or perhaps slightly narrower. I made the door on the side 28" wide. Narrowing the windows 1mm more might make it look a little better and I may do that.

Based on the door height, it appears that the set of windows next to it is 80" wide. Also using that 80" measurement, I got an estimate of about 4.4" for each strip in the awning. That gives me an overall dimension of almost 11', which is a good match to the 10'-12' estimate I had based on the Sanborn Map.

So that's my sketch so far. It will be pretty easy to construct the basic building of styrene, although I may have one or two of my architectural experts double-check my math first. Although this is one of those situations where I may just eyeball some tweaks to make the windows more rectangular and the end a little wider. In theory, though, this should be pretty accurate. In the absence of other evidence, I'll probably put four windows on the far end (or make a blind end and one with windows). I think I may try the photographic paper for the cinder block foundation as well.

Now I just need to figure out what the colors were...so I asked on one of the New Britain Facebook groups. Naturally I got a bunch of answers. Pale yellow with red lettering or a variation was mentioned by several. A couple mentioned green lettering. White and Blue. Maroon and yellow.

Then I remembered it would probably show up in a Kent Cochrane video, c1953-6:

It's the only color reference I have and clearly a maroon red in color. While I don't have the exact date that the automatic gates with flashing lights were installed, the photo dated 1960 has them, and this is the older manual gates so this is clearly earlier.

Because of the photos of the building abandoned, I thought the darker color scheme was the last one.

A little more digging shows that in the 1955 Thomas Airviews photo it is a lighter color:

That would indicate that the Cochrane video was earlier than 1955, and this is correct through at least 1950. Because the Cochrane video was filmed from an RDC, it must have been sometime between late '52 (probably early '53) and before it was repainted c1955.

So it looks like this is the best photo I have for the appearance in my era: