So here it is, a week, a week and a half, ummm, nearly two weeks since my last post. After being very consistent all year, my busy schedule has caught up with me. In this case it's been extra hours at all of my work/business endeavors, plus it was my birthday, etc.

That's not to say that I haven't been able to do anything.

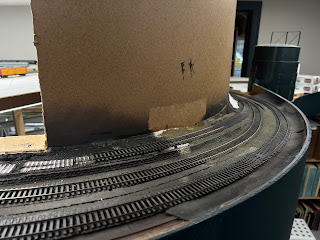

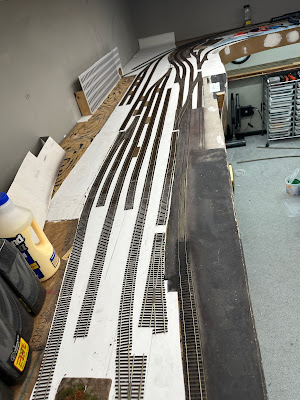

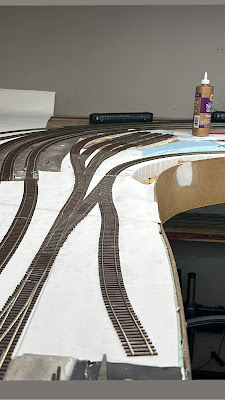

After the last post, I was able to finish soldering all of the feeders to the rail at Whiting St. Yard that evening. I have also connected enough under the layout that it's even operating!

AML Modeling buddy Mark Stafford pointed me in the direction of Krone connectors. These are a type of punch block (well, several types) where you can terminate dozens of wires that are then connected to an output wire. In the US we have similar punchdown blocks for phone, and sometimes network systems. These look like a great idea, but getting it done now was more important, so I went ahead with my original plan of wire nuts and T-Tap Connectors.

As is typical, a few models have crossed the desk. I started working on a Wright Track (ex-Smoky Mountain Model Works, potentially available from Southbound Model Works & Decal Co). This has turned out to be quite a challenge, which I'll explain when I get to actually building it. I also cleaned up all the parts for a Resin Car Works DSS&A box car. This will be a fun (and quick) build, just not sure when.

Work at CNZR has been great, naturally. I take a lot of photos like these:

Bloomfield freight house from Wintonbury St.

A frosty morning at Savin Road.

Two ex-B&M Pullman PS-4 50-ton flat cars.

Morning (prior to daylight savings) at Tobey St.

There's also a lot of wildlife, like this deer right near the Copaco cattle chute.

I've seen bobcats, foxes, turkeys, a bear, lots of snakes and frogs, a very large praying mantis, and others I'm probably forgetting.

For fun I sent my daughter a few pictures like these:

There's a frog in this photo.

There are two frogs in this one.

But I'm not sure how much of this I want to keep including things like these on a blog about modeling and my layout. So I've decided to start

a group on Facebook where I can post things like this, and also be able to communicate more directly. It's also a place where I can provide more informal updates and previews for what will often end up on the blog.

You can let me know in the comments what you think, and of course on the Facebook Group.

--

I plan on trying to post to this blog weekly (instead of the three times/week I've been doing for about the last year). I have several posts in progress, but there are a few other priorities right now:

1. Complete the update of the website (I have to switch over by the end of the year).

2. Finish a clinic for the December Hindsight 20/20 meet.

3. Build a website for a friend's model train business - I'm very excited about this one, but can't say anything else yet...

In addition, I'll have work, business, and family things to manage, with Thanksgiving and Christmas right around the corner.

Posts I'm working on:

1. A tour of my buddy Dale's layout.

2. Modifications to a couple of Rapido's X31a models.

3. (Semi) handlaid switches with CVMW tie strips and Proto 87 Stores parts, among others (I have to build two), and Fast Tracks Diamond Line crossing.

4. More work on the Proto S-1, Atlas S-2, Bachmann/W&R 44-tonners, and Crown Custom I-2 locomotives.

5. Upgrading NE-5 and NE-6 cabooses.

--

So that's where things stand today. It's really adding 40+ additional hours working at the railroad that has restricted the amount of time I have to work on the layout/blog for now. But it's an adjustment, and it's not uncommon for me to get more accomplished when I'm very busy compared to when I have more free time.

.jpg)