"...developed by New Haven officers in cooperation with engineers of the International Business Machines Corporation. Studies first projected in 1940 by the New Haven's transportation and communications departments culminated in a definite plan in 1942, but, because of war-time priorities, equipment was not received until the latter half of 1945 when operation was commenced between Maybrook, Cedar Hill, and the car service office at New Haven."

Another New Haven First!

Revolutionary developments in the handling of interchange reports and train consists are being put into effect by the Car Service Department. They represent the first civilian adaptation of techniques used during the war by the Army Air Forces and the Office of Defense Transportation in Port Control work.

...each yard will receive detailed train consists showing all pertinent information on each car in the train well in advance of the train's arrival at the yard. This will enable the yard to know exactly what is coming and allow it to plan its work before the train has arrived.

Already installed between Maybrook, Cedar Hill and the Car Service Office, the new procedures will be extended to Bay Ridge, Oak Point, Hartford, Springfield, Worcester, Northup Avenue, Framingham and Boston.

Prompt transmission of this information and its quick availability also will forestall many of the telephone calls now being made to various interchange points and yards. For example, since January 15 the Car Service Office at New Haven has been furnishing most of the car records and passing information that previously was only available at Maybrook. This will relieve the already crowded telephone circuits and should make for general improvement in telephone service.

As soon as the train reaches us at Maybrook, the bills are forwarded to the General Yard Office through a pneumatic tube and cards are punched from the bills on a printing key punch which types across the top of the card as it punches holes in the body of the card. Punched and typed on these cards is the car initial and number, contents, kind of car, gross tons, billing road and route, arrival train and time and data of arrival, the origin, shipper, consignee and destination.

These cards are then put through a card-controlled tape punch which cuts a teletype tape. The tape is put through the teletype printer which simultaneously prints the interchange report (at Maybrook this is the inbound consist) for Maybrook's use and transmits it to the Car Service Office.

After the cards have been used to make the tape, they are racked with the bills in the eastbound bill rack, awaiting departure in an outbound train.

When the track check for the outbound train is received at the yard office, the bills with the cards are pulled from the rack and arranged in the outbound train order. The cards are then separated from the bills and put through the card-controlled tape punch to cut a teletype tape, which is put through the teletype printer to print the outbound train consist and simultaneously transmit it to the Car Service Office and to Cedar Hill. After the train has departed, the cards are sorted in car number order and filed for index record purposes.

Under these operations, it is no longer necessary to sheet by hand the inbound train consist, type the interchange report and write up by hand the outbound train consist or wheel report, nor post the records manually to index books.

When the advance consist of a train departing from Maybrook is received at Cedar Hill, a teletype tape is produced at the same time as the consist is being printed. The printed sheet goes to the various clerks at Cedar Hill for checking diversions, etc., while the tape is put through the printing punch to produce a card covering the cars in the train.

These cars are held until the arrival of the train when - after necessary checking and making out of new cards for any cars that might have been picked up enroute - they are used to make a teletype tape and print a final inbound consist, which is transmitted to the Car Service Office. This final inbound consist becomes the wheel report in the Car Service Office.

Following this, the cards at Cedar hill are racked with the bills and the same cycle of operation as occurred at Maybrook is repeated to secure an outbound consist of a train as it leaves Cedar Hill.

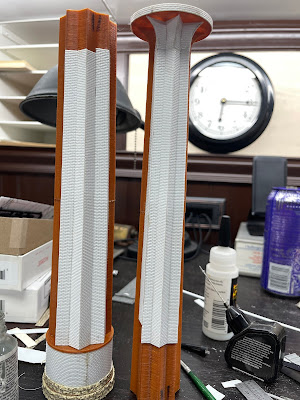

12 a. Interchange Report of receipts from the Erie at Maybrook prepared from cards punched from bills, in lieu of typing from hand-written train sheets.

b. Advance Outbound Consist of OB-2, printed from punched cards and transmitted to Cedar Hill, Supt. of Frt. Trans. and Supt. of Car Service immediately after departure of the train from Maybrook. Inbound train reference appears after each car on outbound consist. Punched record cards for (c) and (d) a loaded car, and (e) and empty.

SFRD 33313 loaded with cauliflower from Mobest, AZ via ATSF-ERIENWX 2269 lettuce from Huma, AZ via SP-ERIEFGEX 51211 lettuce from Blythe, CA via ATSF-ERIERD 24663 lettuce from Blythe, CA via ATSF-ERIE (with typos)BREX 75825 GRJC (?) and it looks like there's a second line for that car

Freight Cars on OB-2 (Maybrook to Boston) January 5, 1946

PFE 93889 carrots from Watsonville, CA via SP-ERIEIC via B&O-ERIECNWMMBKNHWFEXWFE

RDG 74107 coal from Meadowbrook, WV via B&O-LNEPRR 348864 empty